38

8. Click “Exit” button to exit the Ethernet interface setup and go back to Diagnostic Tool main screen.

Factory Default button

This function will reset the IP, subnet mask, gateway parameters obtained by DHCP and reset the

printer name.

Web setup button

Except to use the Diagnostic Utility to setup the printer, you can also explore and configure the printer

settings and status or update the firmware with the IE or Firefox web browser. This feature provides

a user friendly setup interface and the capability to manage the printer remotely over a network.

6. Troubleshooting

6.1 Common Problems

The following guide lists the most common problems that may be encountered when operating this

bar code printer. If the printer still does not function after all suggested solutions have been invoked,

please contact Advanced Labelling Ltd for assistance.

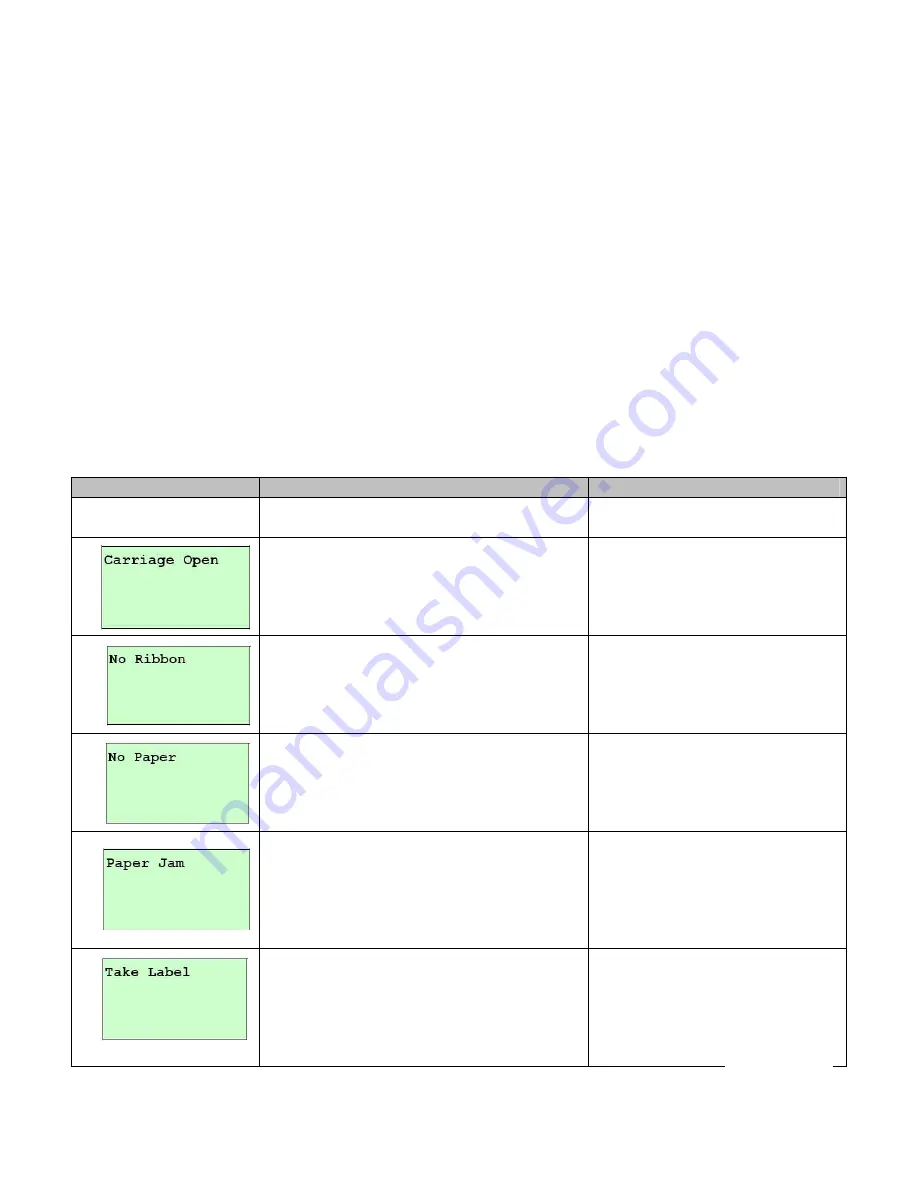

Problem

Possible Cause

Remedy

Power indicator does

not illuminate

Power cord not properly connected.

Restore good connection.

Printer carriage open.

Fully close printer carriage.

Running out of ribbon.

Ribbon installed incorrectly.

Load with new ribbon.

Check ribbon path through

printer.

Running out of label.

Label installed incorrectly.

Gap/black mark sensor out of calibration.

Load with new label.

Check label path through

printer.

Recalibrate gap/black mark

sensor.

Gap/black mark sensor out of calibration.

Paper size does not match software

setting.

Label stuck inside printer mechanism.

Recalibrate gap/black mark

sensor.

Review measurements

specified in labelling software.

Inspect printer mechanism and

clear blockage.

Peel function enabled.

If peeler module installed,

remove label.

If no peeler module installed,

disable peel function.

Check connections to peeler

module.

continued…