LM3612 PRINT & APPLY SYSTEM

USERS MANUAL

Page 18

Made in the U.S.A.

© 2021 LabelMill

06/01/2021 Model LM3612

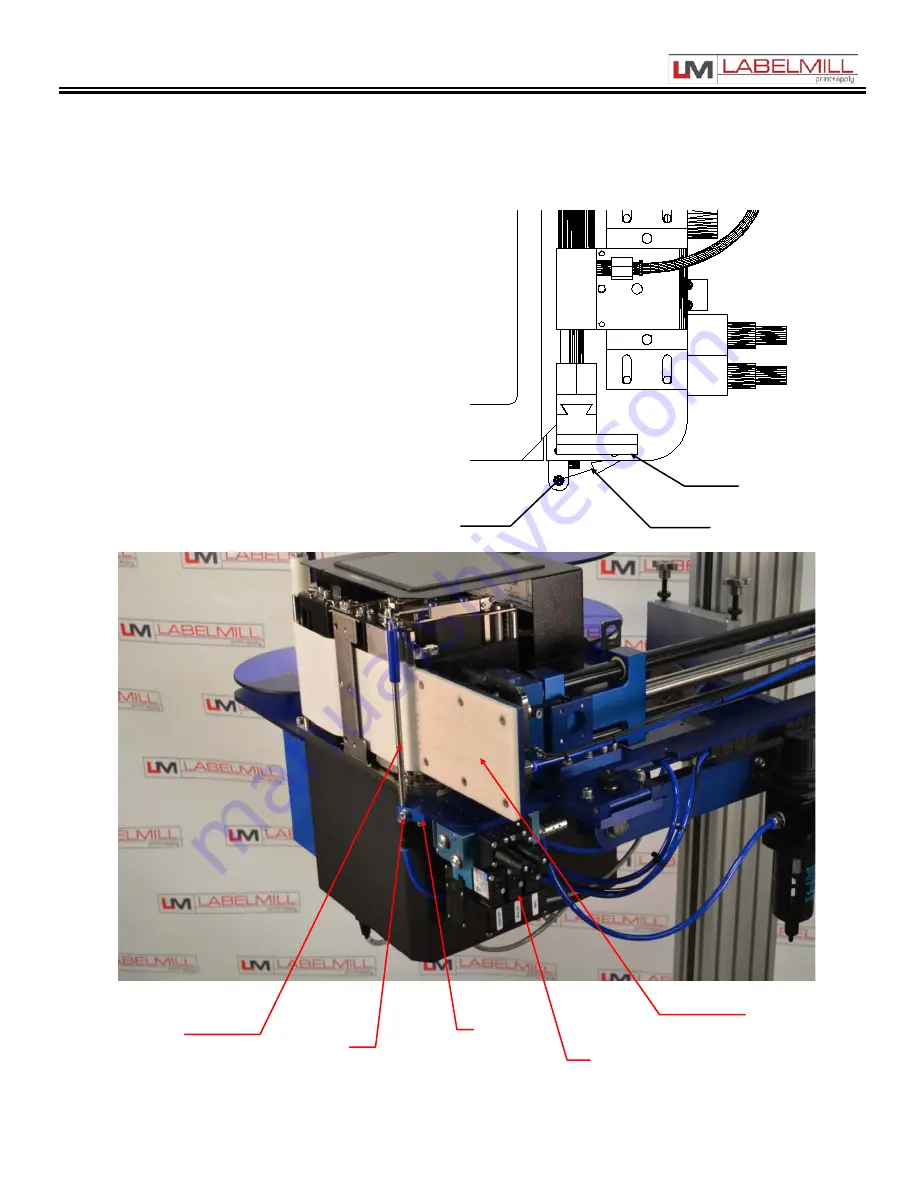

AIR ASSIST TUBE

2-09

The Air Assist Tube must be adjusted to

clear the trailing edge of the printed labels

and the Label Platen. An adjustment

screw is used to adjust the position of the

air holes in relation to the labels. An angle

of 45 degrees is required.

One slot is provided to make the

appropriate adjustments desired.

Air Assist

Tube

Label Platen

Airflow

Mount

Bracket

Air

Assist

Tube

Clamp screw

Label

Platen

Valve Pack