Shock Dyno

Version: 1.0.23241

Page 36/62

9.8.

Graph Types

This section describes the different graph types available for each test.

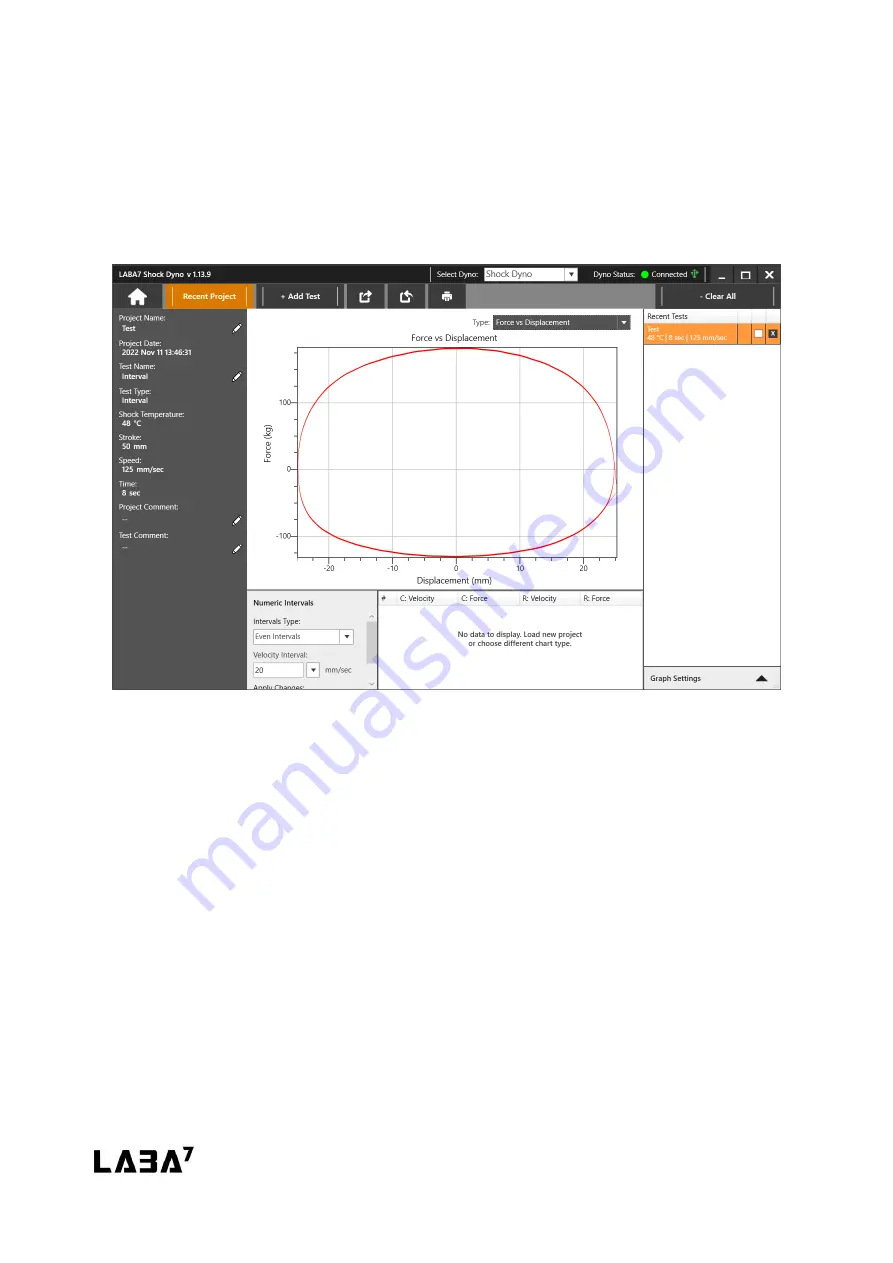

Force vs Displacement

Figure 27

Force vs Displacement is a default graph presented upon launching the application. It is also used

for the live test preview whenever a test is being performed.

The horizontal axis represents the displacement. 0 indicates the middle position of the stroke.

The vertical axis represents the force. The positive force in the upper half of the graph represents

the compression cycle, and the negative force in the bottom half of the graph represents the

rebound cycle.

The left side of the compression and the right side of the rebound represents the speed-up, and

the right side of compression and the left side represents the slow-down of corresponding cycles.