Pennant Pool Heater

Page 7

(5.5 square cm/kW) of total input rating of all

equipment in the enclosure. When communicating to

the outdoors through horizontal ducts, each opening

shall have a minimum free area of not less than

1 square inch per 2000 Btu/hr (11 square cm/kW) of

total input rating of all equipment in the enclosure.

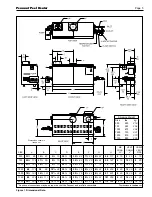

Table 3 shows data for this sizing method, for each

Pennant model.

Method 2

: One permanent opening, commencing

within 12 inches (30 cm) of the top of the enclosure,

shall be permitted. The opening shall directly

communicate with the outdoors or shall communicate

through a vertical or horizontal duct to the outdoors or

spaces that directly communicate with the outdoors

and shall have a minimum free area of 1 square inch

per 3000 Btu/hr (7 square cm/kW) of the total input

rating of all equipment located in the enclosure. This

opening must not be less than the sum of the areas of

all vent connectors in the confined space.

Other methods of introducing combustion and

ventilation air are acceptable, providing they conform

to the requirements in the applicable codes listed

above.

In Canada, consult local building and safety

codes or, in absence of such requirements, follow

CAN/CGA B149.

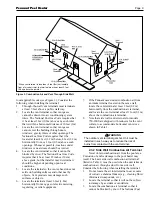

2.1.2 Intake Combustion Air

Never obtain combustion air from the pool area.

Corrosion of and/or damage to the pool heater may

result. The combustion air can be taken through the

wall, or through the roof. When taken from the wall, it

must be taken from out-of-doors by means of the

Laars horizontal wall terminal (see Table 2). When

taken from the roof, a field-supplied rain cap or an

elbow arrangement must be used to prevent entry of

rain water (see Figure 2).

Use single-wall galvanized pipe, per table 4,

for the combustion air intake (see Table 1 for

appropriate size). Route the intake to the heater as

directly as possible. Seal all joints with tape. Provide

adequate hangers. The unit must not support the

weight of the combustion air intake pipe. Maximum

linear pipe length allowed is 50 feet (15.2m). Three

elbows have been calculated into the 50-foot (15.2m)

linear run. Subtract 10 allowable linear feet (3.0m) for

every additional elbow used (see Table 1). When

fewer than 3 elbows are used, the maximum linear

pipe length allowed is still 50 feet (15.2m).

The connection for the intake air pipe is on the

filter box. The Pennant appliances may have venting

and combustion air ducting attached to the top or the

back. They are shipped with the connections at the

top. For attaching either or both pipes to the back, the

mounting flanges are reversible by removing the

mounting screws and orienting the flanges in the

desired position. Replace the screws after positioning

flanges. Run a bead of silicone around the collar and

slide the pipe over the collar. Secure with sheet metal

screws.

In addition to air needed for combustion, air shall

also be supplied for ventilation, including all air

required for comfort and proper working conditions

for personnel. The Pennant loses less than 1 percent of

its input rating to the room, but other heat sources may

be present.

2.2 Venting

2.2.1 Vent Categories

Depending upon desired Pennant venting, it may

be considered a Category I or a Category III

appliance. In general, a vertical vent system will be a

Category I system. However, in rare instances, a

Pennant’s vertical vent system may be considered

Category III. In the U.S., the National Fuel Gas Code

(American National Standard Z223.1-Latest Edition),

or in Canada the CSA B149.1 (latest edition), defines

a Category I vent system, and includes rules and tables

to size these vent systems. If the Pennant’s vertical

vent system does not satisfy the criteria for Category I

venting, it must be vented as a Category III system.

All Pennant vent systems which discharge

horizontally (without the use of a power venter) are

considered Category III vent systems.

Figure 2. Combustion Air and Vent Through Roof.

TERM

DESCRIPTION

Pipe

Single-wall galvanized steel pipe, 24 gauge

minimum (either insulated or non-insulated)

Joint

Permanent duct tape or aluminum tape

Sealing

Table 4. Required Combustion Air Piping Material.

Summary of Contents for Pennant PNCP 1000

Page 28: ...LAARS Heating Systems Page 28 Figure 9 Sheet Metal Components...

Page 29: ...Pennant Pool Heater Page 29 Figure 10 Internal Components...

Page 32: ...LAARS Heating Systems Page 32 Figure 13 Pennant 1250 2000 Ladder Diagram...

Page 33: ...Pennant Pool Heater Page 33 Figure 14 Pennant 500 1000 Wiring Schematic...

Page 34: ...LAARS Heating Systems Page 34 Figure 15 Pennant 1250 2000 Wiring Schematic...

Page 35: ...Pennant Pool Heater Page 35 Figure 16 Field Wiring PNCP 500 1000...