Mini-Therm II Hydronic Boiler

Page 5

Distance

From Gas

Meter

Boiler Size

50

75

100

125

160

225

Pipe Size

0-50'

1/2

3/4

3/4

3/4

1

1

0-15m

50-100'

3/4

3/4

3/4

1

1

1-1/4

15-30m

100-200'

3/4

1

1

1

1-1/4

1-1/4

30-60m

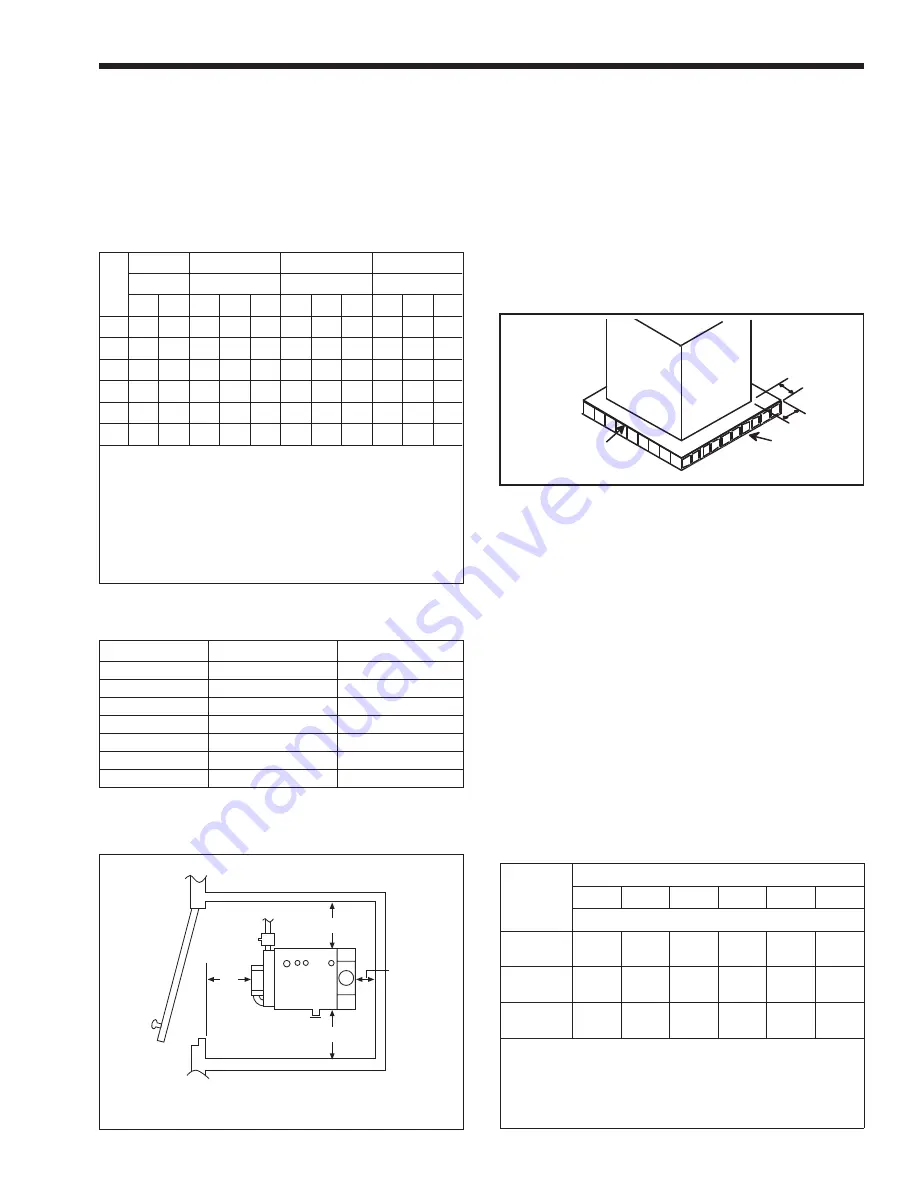

Figure 2. Closet and Alcove Installation (see Table 3).

consisting entirely of a combination of steel, iron,

brick, tile, concrete, slate, glass or plaster.

All boilers can be installed on a combustible

floor if a non-combustible base assembly, available

from Laars, is used. See the boiler rating plate for the

appropriate base part number. Boilers must never be

installed on carpeting.

As an alternative to the Laars non-combustible

base plate, the National Fuel Code allows a boiler to

be placed on other than a non-combustible surface

when such an installation complies with the American

Insurance Code. This code specifies the surface under

the boiler be protected with hollow masonry no less

than 4" (102mm) thick, covered with sheet metal at

least 24 ga. in thickness. Such masonry must be laid

with ends unsealed, and joints matched in such a way

as to provide a free circulation of air from side to side

through the masonry (see Figure 3).

Dimensions in inches (mm).

1F. Gas Supply and Piping

Review the following instructions before

proceeding with the installation.

1.

Verify that the boiler is fitted for the proper

type of gas by checking the rating plate. Laars

boilers are normally equipped

to operate below a 2000 foot altitude. Boilers

equipped to operate at higher altitudes have

appropriate stickers or tags attached (next to the

rating plate).

2.

Use the figures in Table 4 to provide adequate

gas piping from the gas meter to the boiler.

3.

A trap (drip leg) must be provided ahead of the

gas controls (see Figure 4). A manual gas shutoff

valve must also be provided for service

convenience and safety. Check the local codes.

Table 3. Minimum Boiler Clearances

From Combustible Surfaces.

Table 4. Gas Piping Sizes.

Size

1/2" Pipe

3/4" Pipe

1" Pipe

1-1/4" Pipe

Pump H.P.

Pump H.P.

Pump H.P.

Pump H.P.

1/25 1/12 1/25 1/12 1/6 1/25 1/12 1/6 1/25 1/12 1/6

50

50

99

390 680

*

*

*

*

*

*

*

75

*

35

160 300 460 640

*

*

*

*

*

100

*

*

77

150 260 330 620

*

*

*

*

125

*

*

27

80

140 170 360 600

*

*

*

160

*

*

*

25

72

57

160 330 190 480

*

225

*

*

*

*

*

*

*

110

*

69

330

*A circular and/or primary/secondary piping are required. Consult

factory.

1. Chart is based on 30°F (-1°C) maximum temperature rise.

2. Calculations are based on Type L copper tubing with one

zone valve and eight elbows.

3. Typical circulating pumps:

1

/

25

HP=Taco 007, B&G LR-20 or

SLC-25, Grundfos UP15-42F, or equivalent.

1

/

12

HP=B&G LR-

12, Grundfos UP26-42F, or equivalent.

1

/

6

HP=B&G series

HV, Grundfos UP43-75, or equivalent.

Table 2. Maximum Suggested Circuit Length in Feet.

Note: These figures are for Natural Gas (.65 Sp. Gr.), and are

based on 1/2" water column pressure drop. Check supply

pressure with a manometer, and local code requirements for

variations. For LPG, reduce pipe diameter one size, but

maintain a 1/2" minimum diameter. A 'normal' number of Tees

and elbows have been taken into allowance.

Figure 3. Typical Combustible Floor Installation.

Sheet Metal Cover

Min. Thickness 24 Gauge

Galvanized

Hollow

Concrete

Block

12"

Min.

Sheet Metal Cover

Min. Thickness 24

Gauge Galvanized

Hollow

Concrete

Block

12" Min.

(305mm)

6 (152)

6 (152)

6 (152)

4*

(102)

*6" for models JV160 to JV225.

Boiler Sizes

50-125

160-225

Clearances

in

mm

in

mm

Left side

6

152

6

152

Right side

6

152

6

152

Rear

6

152

6

152

Front

4

102

6

152

Flue

6

152

6

152

Top

23

484

36

914