Strada EP

7

www.lamarzocco.com

V1.0

4. Operating the Espresso Machine and Preparing Coffee

1)

Starting the Espresso Machine

Filling the Boilers with Water:

Once the installation procedures have been completed, it is

necessary to

fi

ll the boiler tanks with water. Complete the

following procedure to properly

fi

ll the boiler tanks:

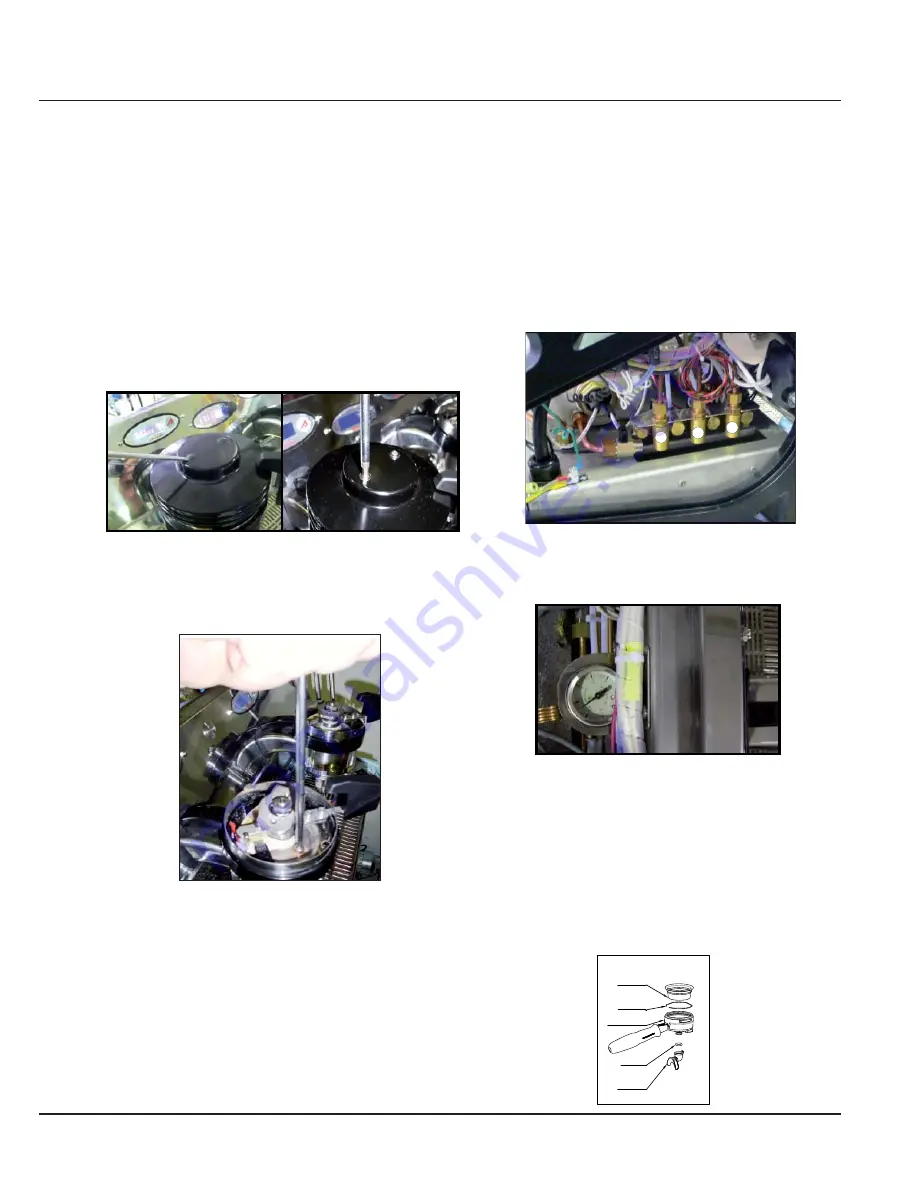

a) Coffee Boiler

The water

fl

ows inside the coffee boilers directly, as soon as the

water system and water

fi

lter/softener valves are opened.

Since the in

fl

ow of water will compress the air in the boiler, it

will be necessary to remove or “bleed” the air from the coffee

boilers. All air must be removed in order to completely “saturate”

the coffee boiler/group assemblies.

To remove the air from the boiler, or “bleed the groups”, it will be

necessary to remove the plastic cap and the handle from the top

of the group.

Loosen the bleed screws one at a time to allow air to escape until

water

fl

ows from below the screw head. Tighten the screw to stop

the water from

fl

owing. Over tightening can cause damage to the

sealing washer and the group cover. Repeat this procedure on

all groups.

b) Steam Boiler

Turn the main switch to position “1” or ON, then push the encoder

knob for three seconds and the automatic steam boiler level

function will be switched on, activating the auto-

fi

ll solenoid

valve and the motor pump. This will

fi

ll the steam boiler to a

predetermined level and will shut off when full.

Note:

Air inside the steam boiler may build up pressure (which

may be detected through the pressure gauge).

Once the pump stops, check the display, the message “Coffee

Boiler Filled?” should be displayed. Push the Encoder Knob to

con

fi

rm that the preceding procedures are complete.

The installation is now complete and the espresso machine

should be heating to operating temperatures.

2)

Waiting for the Espresso Machine to Heat to

Operating Temperature

During this time, it may happen that the pointer of the coffee

boiler pressure reaches as high as 14-15 bar. This may happen

anytime that the heating element is in the “on” condition. In

this case, it is necessary to adjust the expansion valve (see the

picture below about the three coffee boiler expasion valves) in

such a way that the pressure never exceeds 13.5bar.

In normal operating conditions, the coffee boiler pressure

transducer, while brewing, can read anywhere from 0-12 bar

when brewing.

GR1

GR1

GR2

GR2

GR3

GR3

The steam boiler pressure is visible through a pressure gauge

placed inside the machine, behind the control and the 1st group.

When the steam boiler reaches operating temperature, the light

on the Tea dispense button will switch on.

Filter

Basket

Basket

Spring

O-ring

Double

Spout

Portafilter

3)

Installing the Portafi lters

Install the porta

fi

lter(s) by inserting them into the group and rotate

the handle from left to right. When the porta

fi

lters are inserted

properly, you can press any of the brew buttons to start the

fl

ow

of water through the porta

fi

lter. ou should allow hot water to

pass through the porta

fi

lter(s) for a few seconds each time, in

order to pre-heat the porta

fi

lter.

Note:

It is important to leave the porta

fi

lters installed in the

espresso machine when not in use. The porta

fi

lter must remain

heated for the brew process to function correctly.