REV5

For any questions please contact us at toll free (877) 482-2040 Mon-Fri 8 a.m. to 4:30 p.m. 28

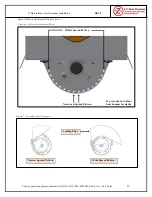

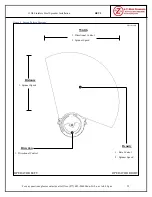

135lb Stainless Steel Spreader Installation

Troubleshooting Cont…

First six lights on controller are

flashing

1. Voltage regulator is bad

1. Replace Voltage Regulator

First seven lights on controller

are flashing

1. Controller is over heating

1. Let controller cool down.

Circuit board needs to cool to

below 60C before the controller

will restart. Turn controller off

then on again to reset.