2BT

1-4-15

Maintenance

Description

item No.

U093

Setting the exposure density gradient

Description

Changes the exposure density gradient in manual density mode, depending on respective image modes (text,

text and photo, photo).

Purpose

To set how the image density is altered by a change of one step in the manual density adjustment. Also used to

make copy image darker or lighter.

Start

1. Press the start key. A selection item appears.

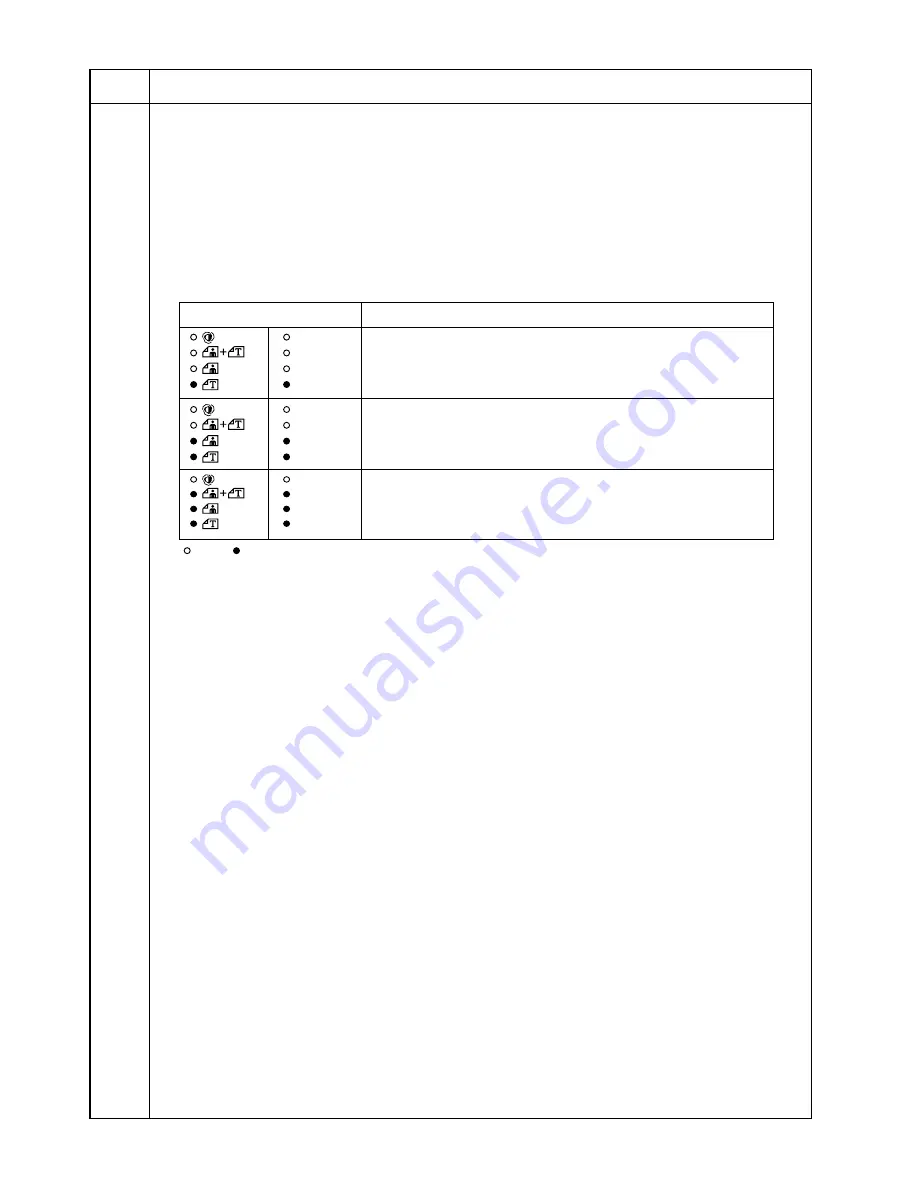

2. Select the image mode to be adjusted by lighting image mode LEDs using the image mode selection key.

3. Press the start key. The machine enters the setting mode.

Image mode LEDs

Description

Photo

Text

Text & Photo

AutoExp.

Density in text mode

Photo

Text

Text & Photo

AutoExp.

Density in text and photo mode

Photo

Text

Text & Photo

AutoExp.

Density in photo mode

: Off,

: On