Disassembly

Disassembly: Main unit printer

FS-6750

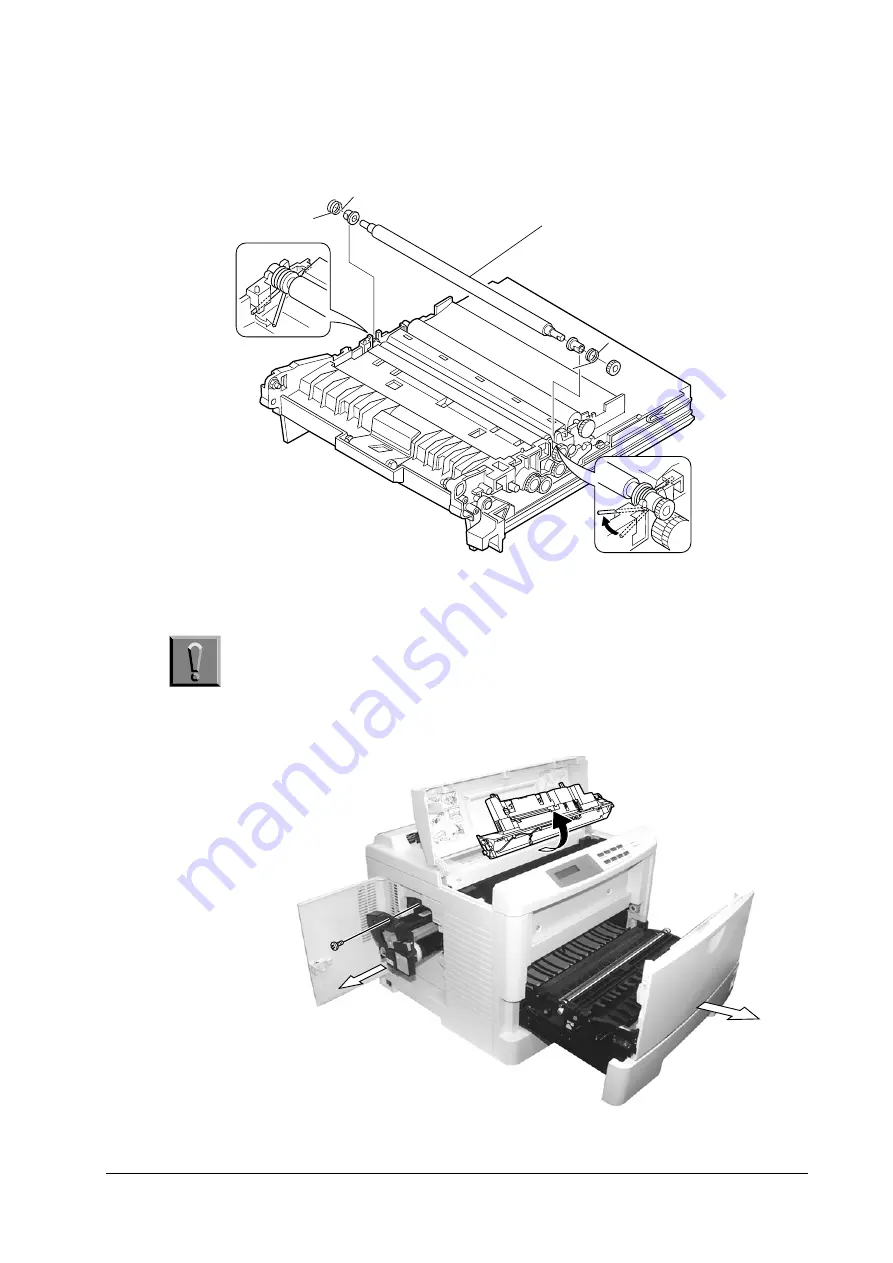

Remove the coil springs that are used to secure and press the top (metal) registra-

tion roller towards the bottom (rubber) registration roller underneath.

Removing the drum unit

Caution

Before removing the drum unit, be sure to remove the developer unit

and draw out the paper feed unit half way. Do not attempt to forcibly

pull out the drum without first having done all of these procedures.

Top regist.

roller

Top regist. roller

1—Remove

this screw and

pull out the

drum unit.

2—Draw the feed

unit half way out.

3—Remove the

developer unit.

Summary of Contents for FS-6750

Page 1: ...SERVICE MANUAL...

Page 6: ...Conventions Preface vi This page left intentionally blank...

Page 120: ...Disassembly Disassembly Option paper feeder 5 24 FS 6750 This page left blank intentionally...

Page 148: ...Troubleshooting Print quality problems 6 28 FS 6750 This page left blank intentionally...