Lubrication Requirements

5-4

KVAL 990-HB Operation / Service Manual

Lubrication Requirements

This section describes the parts of the machine that require periodic lubrication, and specifies the

lubricants. In addition, it explains how to maintain the lubrication systems on the machine.

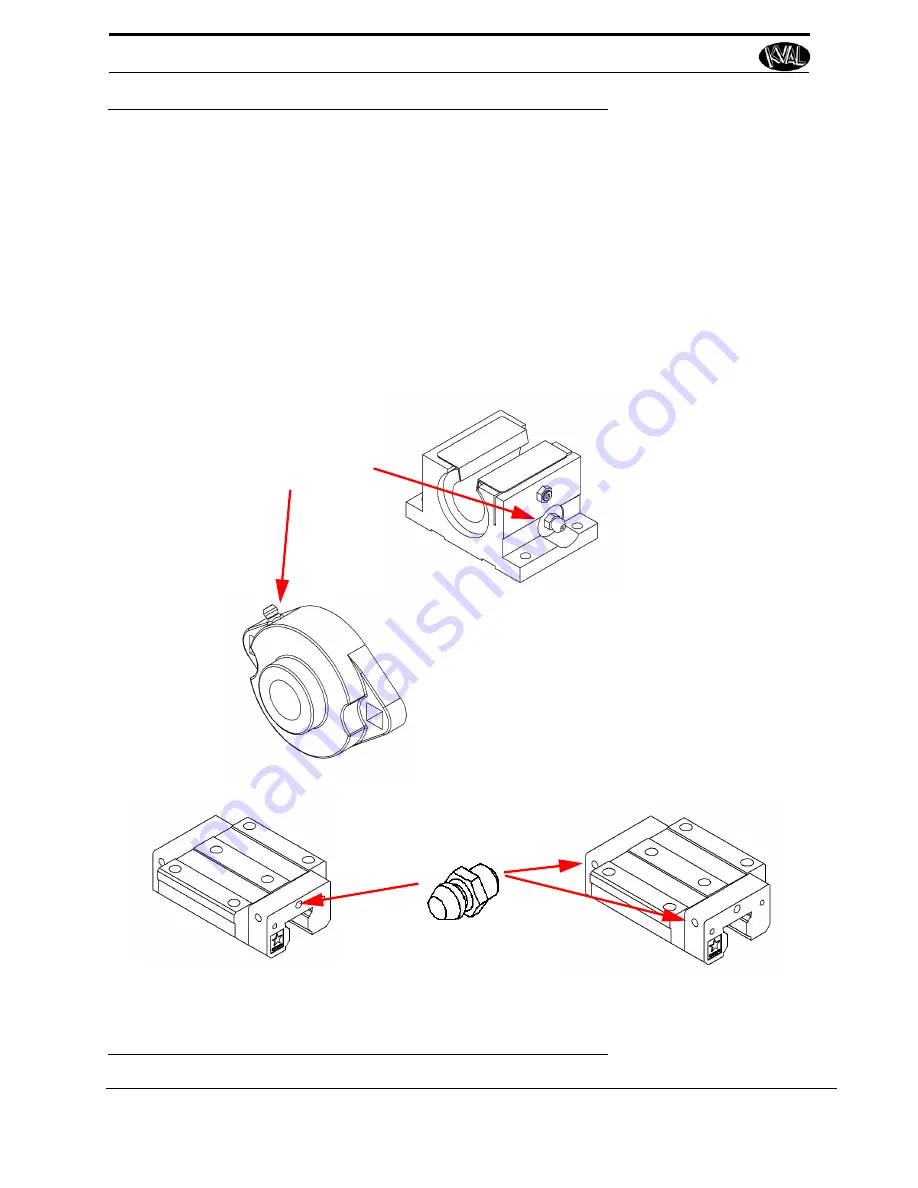

Linear Bearings, Flange Bearing, and Pillow Blocks

If the bearing is equipped with a grease fitting (Zerk Fitting), it should receive 1 Gram (one pump

from grease gun) of Dura-Lith Grease (KVAL P/N Lube EP-2) every 250 hours of operation.

Note:

Bearings without grease fittings have been pre-lubricated at the factory and do

not require further lubrication.

Zerk Fittings

Zerk Fitting Location

Depends on Position of

Slide

FIGURE 5-13.

Zerk Fittings

Summary of Contents for 990-HB

Page 4: ...KVAL 990 HB Operation Manual ...

Page 25: ...Safety Sign Off Sheet 1 17 KVAL 990 HB Operation Service Manual ...

Page 26: ...Safety Sign Off Sheet 1 18 KVAL 990 HB Operation Service Manual ...

Page 66: ...Diagnostic Screen 2 40 KVAL 990 HB Operation Service Manual ...

Page 84: ...Calibration of the Back Section 3 18 KVAL 990 HB Operation Service Manual ...

Page 88: ...System IT Administration 4 4 KVAL 990 HB Operation Service Manual ...