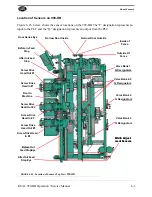

Mechanical set up of the 990-HB

5-19

KVAL 990-HB Operation / Service Manual

First clamp door against the stop that the machine is set-up for. Normally the back sec-

tion shifts away from the door stop that is being used. Also, depending what your

hinge locations are from the top of the door, down to the back section location will

vary from one machine to the next.

The standard set-up would be 2 inches of stop pin in both stop locations to equal 44

from the top to the center line of the lock bore.

NOTE:

Before changing the lock bore location, turn power OFF, as well as the air

supply at the slide valve located next to the back section valve bank where the air sup-

ply enters the back section. To change the lock bore location, you can add or subtract

pins to achieve the desired position to remove stop pins; for small adjustments, you

can simply change the bolt.

Setting Up Lock Bore Backset

The lock bore backset (the distance from the center line of the lock bore to the door's

edge) is controlled by four adjustable turret stops. KVAL's factory setting for the lock

bore turrets accommodates 5", 2.75" and 2.375".

If No Auto Backset on 990-HB: Side Drill (Latch Hole)

The side drill bit has a 4-inch long fluted section. A 6-inch bit is necessary for backsets

and over-bored deadbolts. Be certain the machine is locked out electrically and the air

service is disconnected. Finally, wait until the bit has come to full stop before getting

out the collet wrenches.

NOTE:Be certain that the face plate router depth is correct and that the router chord is

fastened to the router as shown; otherwise, the long bit will eat the router.

Lock Bore Diameter

Lock out air and electrical service. Use collet wrenches to put in the appropriate face

boring bit. Replace chip out block with a new one, or a block previously used for the

hole diameter.

Plate Width: Plate Router Vertical Travel

Plate router vertical travel is established by rotating stop turrets like those found on the

hinge section. These turrets have four positions: set-ups for 1" and 1/8” for either

square edge or three-degree beveled edge. These bolts are color-coded:

• Red=1” square edge

• Blue=1-1/8” square edge

• Silver=1” beveled edge

• White=1-1/8” beveled edge

Notice that no change need be made to these turrets to change among doors of varying

thickness since the lock section centers the door when it clamps. If for some reason the

faceplate is not centered on the latch hole, you can adjust the screws that contact the

turret bolts. If both the plate and latch hole are off-center, contact KVAL for instruc-

Summary of Contents for 990-HB

Page 4: ...KVAL 990 HB Operation Manual ...

Page 25: ...Safety Sign Off Sheet 1 17 KVAL 990 HB Operation Service Manual ...

Page 26: ...Safety Sign Off Sheet 1 18 KVAL 990 HB Operation Service Manual ...

Page 66: ...Diagnostic Screen 2 40 KVAL 990 HB Operation Service Manual ...

Page 84: ...Calibration of the Back Section 3 18 KVAL 990 HB Operation Service Manual ...

Page 88: ...System IT Administration 4 4 KVAL 990 HB Operation Service Manual ...