48

3BA00044-00 • 2013-05-23 • Rev. 4

ersa DIGITAL 2000 A

5.2.2

Description of the Flow Chart

Starting from the actual value display, the next menu point in each case is reached via

the ENTER key. The sequence of menu items (parameter settings) is shown in the flow

chart in Figure 4. Each parameter setting is carried out via the (+) and (-) keys. You can

jump back to the actual value display from any menu item by double-clicking (pressing

twice) the ENTER key.

The symbol for the given menu item flashes in the fourth position. If no input is made

within 8 seconds, the station returns to the actual value display. All parameter settings

are saved and take effect immediately.

5.2.3

Abbreviated Procedure

The double-click function has been integrated for easier parameter setting. Once you

have carried out a parameter setting within the flow chart (see Figure 4), you can return

to the actual value display by double-clicking (pressing twice) the ENTER key. By again

double-clicking in the actual value display, you can now follow a branch from the last

selected menu item. Running through the entire menu is not

necessary

5.3

Description of the Functions

5.3.1

Setpoint Function (

o

)

The desired soldering tip temperature setpoint is set in the first menu item (see flow

chart in Figure 4) by means of the (+) and (-) keys. The different soldering irons have dif

-

ferent temperature ranges. These ranges are specified in Table 3. The set value adjust

-

ment does not have any function with the temperature sensor.

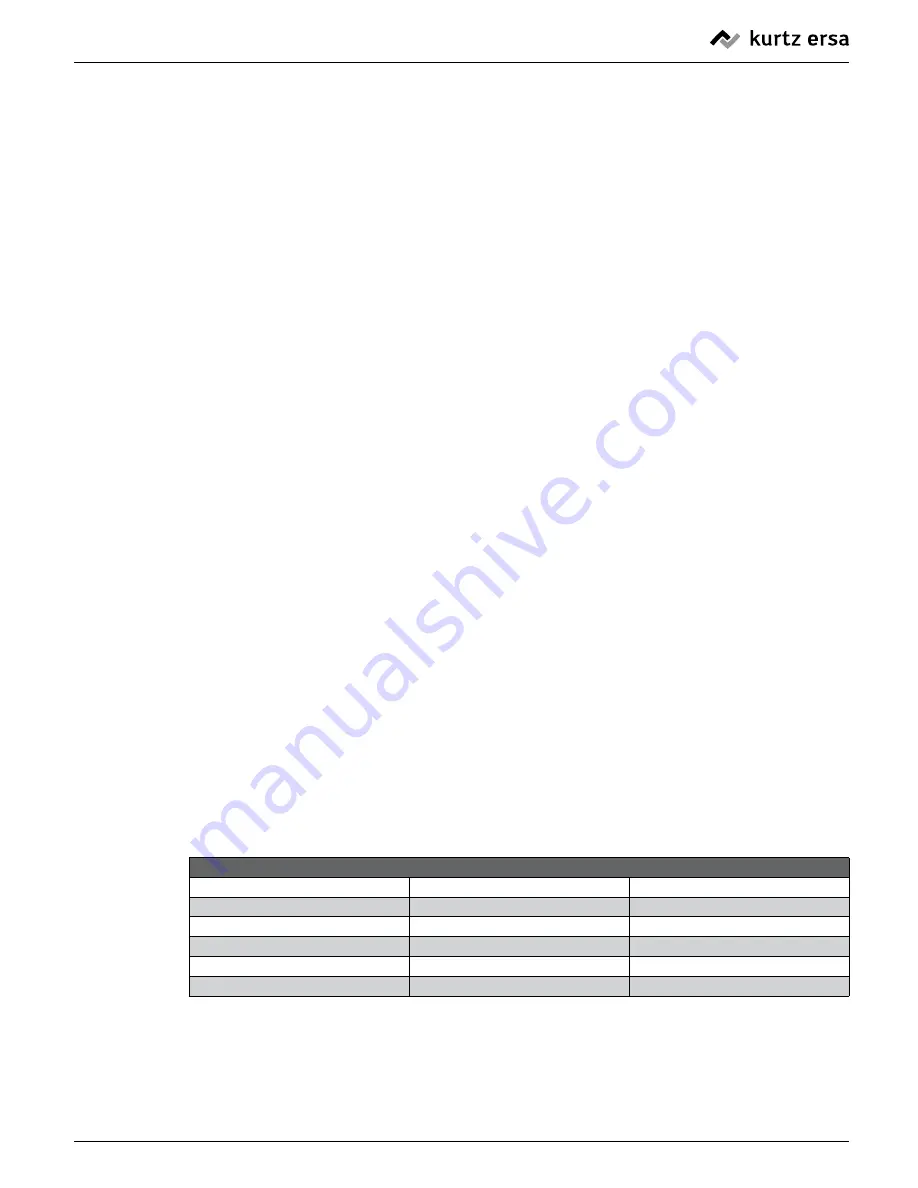

Table 3: Temperature ranges of the individual soldering irons

Tool

Lower temperature bound

Upper temperature bound

TECH TOOL

50

°

C/120

°F

450

°

C/850

°F

POWER TOOL

50

°

C/120

°F

450

°

C/850

°F

X-TOOL

50

°

C/120

°F

450

°

C/850

°F

MICRO TOOL

150

°

C/300

°F

450

°

C/850

°F

CHIP TOOL

150

°

C/300

°F

450

°

C/850

°F

Functional description