G-22

ZD21N-EC, ZD21-EC, ZD28-EC, WSM

G GENERAL

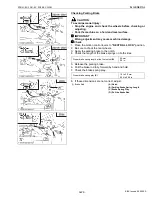

[5] CHECK POINTS OF EVERY 50 HOURS

Checking Safety Device

CAUTION

To avoid personal injury:

• Do not allow anyone near the machine while testing.

• If the machine does not pass one of the following tests, do

not operate the machine.

• Sit on operator’s seat for all tests except for Test 1.

■

Test 1 (OPERATOR NOT ON THE SEAT)

1. Securely set the parking brake.

2. Shift the PTO lever (4) to “DISENGAGE” (OFF) position.

3. Set the motion control levers (3) to the “NEUTRAL LOCK”

position.

4. Turn the key switch (5) to “START” position.

5. The engine must not crank.

■

Test 2 (OPERATOR ON THE SEAT)

1. Do not set the parking brake. (Release it from test 1.)

2. Shift the PTO lever (4) to “DISENGAGE” (OFF) position.

3. Set the motion control levers (3) to the “NEUTRAL LOCK”

position.

4. Turn the key switch (5) to “START” position.

5. The engine must not crank.

■

Test 3 (OPERATOR ON THE SEAT)

1. Securely set the parking brake.

2. Shift the PTO lever (4) to “DISENGAGE” (OFF) position.

3. Grasp the motion control levers (3) and move then inward from

“NEUTRAL LOCK” position to “NEUTRAL” position and then

release the levers.

4. Turn the key switch (5) to “START” position.

5. The engine must not crank.

■

Test 4 (OPERATOR ON THE SEAT)

1. Securely set the parking brake.

2. Shift the PTO lever (4) to “ENGAGE” (ON) position.

3. Grasp the motion control levers (3) and move then inward from

“NEUTRAL LOCK” position to “NEUTRAL” position and then

release the levers.

4. Turn the key switch (5) to “START” position.

5. The engine must not crank.

■

Test 5 (OPERATOR ON THE SEAT)

1. Start the engine.

2. Keeps the parking brake securely set.

3. Shift the PTO lever (4) to “DISENGAGE” (OFF) position.

4. Grasp the motion control levers (3) and move then inward from

“NEUTRAL LOCK” position to “NEUTRAL” position and then

release the levers.

5. The engine must shut off after a short time delay.

IMPORTANT

■

• For this test only, the engine will shut off in a few seconds.

(1) Parking Brake Lock Pedal

(2) Parking Brake Release Lever

(3) Motion Control Lever

(4) PTO Lever

(5) Key Switch

KiSC issued 09, 2006 A

Summary of Contents for ZD21-EC

Page 1: ...ZD21N EC ZD21 EC ZD28 EC WORKSHOP MANUAL ZERO TURN MOWER KiSC issued 09 2006 A ...

Page 7: ...5 ZD21N EC ZD21 EC ZD28 EC WSM SAFETY INSTRUCTIONS KiSC issued 09 2006 A ...

Page 8: ...6 ZD21N EC ZD21 EC ZD28 EC WSM SAFETY INSTRUCTIONS KiSC issued 09 2006 A ...

Page 11: ...9 ZD21N EC ZD21 EC ZD28 EC WSM DIMENSIONS DIMENSIONS KiSC issued 09 2006 A ...

Page 12: ...G GENERAL KiSC issued 09 2006 A ...

Page 59: ...1 ENGINE KiSC issued 09 2006 A ...

Page 60: ...CONTENTS MECHANISM 1 FUEL SYSTEM 1 M1 1 GOVERNOR 1 M1 KiSC issued 09 2006 A ...

Page 138: ...2 TRANSAXLE KiSC issued 09 2006 A ...

Page 178: ...3 FRONT AXLE KiSC issued 09 2006 A ...

Page 179: ...CONTENTS MECHANISM 1 STRUCTURE 3 M1 KiSC issued 09 2006 A ...

Page 187: ...4 HYDRAULIC SYSTEM KiSC issued 09 2006 A ...

Page 202: ...5 ELECTRICAL SYSTEM KiSC issued 09 2006 A ...

Page 205: ...5 M2 ZD21N EC ZD21 EC ZD28 EC WSM ELECTRICAL SYSTEM ZD28 KiSC issued 09 2006 A ...

Page 206: ...5 M3 ZD21N EC ZD21 EC ZD28 EC WSM ELECTRICAL SYSTEM ZD21N ZD21 KiSC issued 09 2006 A ...

Page 207: ...5 M4 ZD21N EC ZD21 EC ZD28 EC WSM ELECTRICAL SYSTEM ZD28 KiSC issued 09 2006 A ...

Page 237: ...6 ROTARY MOWER KiSC issued 09 2006 A ...

Page 238: ...CONTENTS MECHANISM 1 POWER TRANSMISSION 6 M1 2 LIFTING MECHANISM 6 M2 KiSC issued 09 2006 A ...