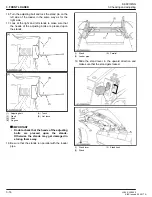

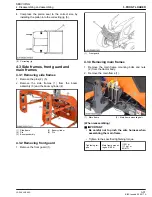

2. Position the tractor squarely in front of the

attachment and tilt the quick-attach-coupler forward

with the bucket cylinder.

(1) Quick attach coupler

3. Ease the quick-attach-coupler-mounting-plate into

the saddle of the attachment.

4. Roll the quick-attach-coupler back using the bucket

cylinder and raise the boom slightly.

The back of the attachment should rest against the

front of the quick-attach-coupler-mounting-plate,

and the weight of the attachment should be

supported by the loader.

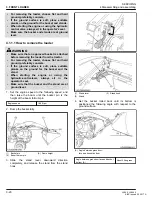

CAUTION

To avoid personal injury or machine damage:

• Raise the boom only enough to latch the

attachment.

The attachment could swing off the quick-

attach-coupler.

(1) Quick attach coupler

5. When the attachment is properly seated in the

saddle and against the front of the quick-attach-

coupler-mounting-plate, turn off the engine and set

the parking brake.

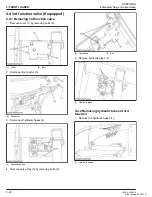

6. Push the quick-attach-coupler-handles to the fully

latched position.

(1) Quick attach coupler handle

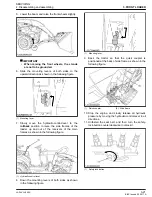

7. Verify that both latching pins are completely

engaged in the base of the attachment.

DANGER

To avoid personal injury or death

• The following engagement points are

critical.

– The lock pins of the quick-attach-coupler

have to protrude into and through the

pin slots of the attachment on both

sides.

It is critical that the lock pins are in good

condition and without visible signs of

wear or damage.

It is critical that the operator align the

quick-attach-coupler of the loader with

the attachment to allow the lock pins to

go through the pin slots.

– Push down both quick-attach-coupler-

handles until the they contact the ear

plates near the points where the pin bolt

goes through the handle.

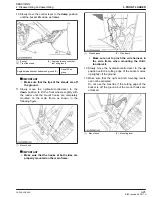

• Do not operate the tractor or attachment

unless all of the preceding conditions are

met.

(1) Handle

(2) Ear plate

(3) Pin slot

(4) Lock pin

(A) Points where the quick at-

tach coupler handle contacts

the ear plate

SERVICING

4. Disassembling and assembling

3. FRONT LOADER

LA344, LA344S

3-27

KiSC issued 02, 2017 A

Summary of Contents for LA344

Page 1: ...LA344 LA344S WORKSHOP MANUAL FRONT LOADER KiSC issued 02 2017 A ...

Page 5: ...1 INFORMATION KiSC issued 02 2017 A ...

Page 9: ...1 INFORMATION SAFETY FIRST 1 4 LA344 LA344S KiSC issued 02 2017 A ...

Page 11: ...1 INFORMATION SAFETY DECALS 1 6 LA344 LA344S KiSC issued 02 2017 A ...

Page 12: ...SAFETY DECALS 1 INFORMATION LA344 LA344S 1 7 KiSC issued 02 2017 A ...

Page 15: ...1 INFORMATION TERMINOLOGY 1 10 LA344 LA344S KiSC issued 02 2017 A ...

Page 20: ...2 GENERAL KiSC issued 02 2017 A ...

Page 22: ...2 GENERAL IDENTIFICATION 2 2 LA344 LA344S KiSC issued 02 2017 A ...

Page 24: ...2 GENERAL 2 4 LA344 LA344S KiSC issued 02 2017 A ...

Page 26: ...2 GENERAL LUBRICATING SYSTEM 2 6 LA344 LA344S KiSC issued 02 2017 A ...

Page 30: ...2 GENERAL TIGHTENING TORQUES 5 Hydraulic fittings 2 10 LA344 LA344S KiSC issued 02 2017 A ...

Page 32: ...2 GENERAL MAINTENANCE CHECK LIST 2 12 LA344 LA344S KiSC issued 02 2017 A ...

Page 36: ...2 GENERAL SPECIAL TOOLS 1 Special tools for loader 2 16 LA344 LA344S KiSC issued 02 2017 A ...

Page 37: ...3 FRONT LOADER KiSC issued 02 2017 A ...

Page 71: ...3 FRONT LOADER SERVICING 5 Servicing 3 34 LA344 LA344S KiSC issued 02 2017 A ...