MAINTENANCE CHECK LIST

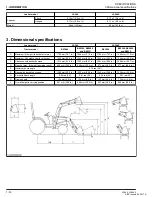

1. Loader service intervals

To keep the machine working in good condition as well as to avoid any accident and trouble, carry out periodic

inspection and maintenance. Check the following points before use.

Service intervals

Check points

Reference page

Daily (Each use)

Check hydraulic hoses.

Every 10 hours

Apply all grease fittings.

Every 50 hours

Check the main frame mounting bolts.

MAINTENANCE CHECK LIST

1.Loader service intervals

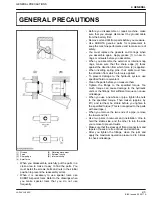

2. GENERAL

LA344, LA344S

2-11

KiSC issued 02, 2017 A

Summary of Contents for LA344

Page 1: ...LA344 LA344S WORKSHOP MANUAL FRONT LOADER KiSC issued 02 2017 A ...

Page 5: ...1 INFORMATION KiSC issued 02 2017 A ...

Page 9: ...1 INFORMATION SAFETY FIRST 1 4 LA344 LA344S KiSC issued 02 2017 A ...

Page 11: ...1 INFORMATION SAFETY DECALS 1 6 LA344 LA344S KiSC issued 02 2017 A ...

Page 12: ...SAFETY DECALS 1 INFORMATION LA344 LA344S 1 7 KiSC issued 02 2017 A ...

Page 15: ...1 INFORMATION TERMINOLOGY 1 10 LA344 LA344S KiSC issued 02 2017 A ...

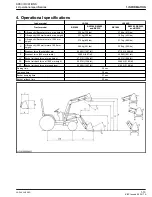

Page 20: ...2 GENERAL KiSC issued 02 2017 A ...

Page 22: ...2 GENERAL IDENTIFICATION 2 2 LA344 LA344S KiSC issued 02 2017 A ...

Page 24: ...2 GENERAL 2 4 LA344 LA344S KiSC issued 02 2017 A ...

Page 26: ...2 GENERAL LUBRICATING SYSTEM 2 6 LA344 LA344S KiSC issued 02 2017 A ...

Page 30: ...2 GENERAL TIGHTENING TORQUES 5 Hydraulic fittings 2 10 LA344 LA344S KiSC issued 02 2017 A ...

Page 32: ...2 GENERAL MAINTENANCE CHECK LIST 2 12 LA344 LA344S KiSC issued 02 2017 A ...

Page 36: ...2 GENERAL SPECIAL TOOLS 1 Special tools for loader 2 16 LA344 LA344S KiSC issued 02 2017 A ...

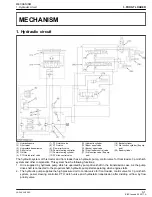

Page 37: ...3 FRONT LOADER KiSC issued 02 2017 A ...

Page 71: ...3 FRONT LOADER SERVICING 5 Servicing 3 34 LA344 LA344S KiSC issued 02 2017 A ...