CHECKS BEFORE START

10

C

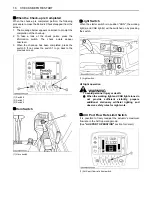

Hour-meter

Indicates the total operating hours of the machine.

How the indicator works

A

The meter advances one hour after an hour of

operation regardless of the engine rpm.

C

Engine tachometer

Indicates the current rpm of the engine.

C

Glow indicator

The indicator is displayed when the starter key is turned

to the

"RUN"

position but the engine requires preheating.

Wait until the indicator goes out, and then start the engine.

B

Warning Lamp

The warning lamp is used to indicate broken wire, short-

circuit, fuel shortage and other problems.

The warning lamp starts flashing in red if any problem

occurs. If the system senses a in warning signal, the

warning lamp starts flashing in yellow.

A

If the warning illuminates, do not just look at the meter;

carry out the appropriate inspection and correction

accordingly.

(See

"REGULAR CHECKS AND MAINTENANCE

WORK"

section)

A

If any warnings and problems are displayed, an alarm

buzzer will beep. (See

"LIST OF SCREENS"

section

for detail.)

A

See your KUBOTA dealer from details concerning

care and maintenance.

(1) Hour-meter

(1) Engine tachometer

(1) Glow indicator

(1) Warning lamp (red, yellow)

Summary of Contents for KX080-4S

Page 10: ......

Page 18: ...SAFE OPERATION 8 ...

Page 19: ... 9 SAFE OPERATION ...

Page 20: ...SAFE OPERATION 10 ...

Page 21: ... 11 SAFE OPERATION ...

Page 22: ...SAFE OPERATION 12 ...

Page 23: ... 13 SAFE OPERATION ...

Page 26: ...DEALER SERVICE 2 1 Engine serial No ...

Page 71: ...47 EXCAVATOR OPERATION ...

Page 130: ...106 LIFTING CAPACITY ...