91

OTHER ADJUSTMENTS AND REPLACEMENTS

OTHER ADJUSTMENTS AND REPLACEMENTS

PURGING OF THE FUEL SYSTEM

1. Fill up the fuel tank with fuel.

2. Turn the starter key to the position "RUN".

3. The air in the fuel system will automatically be purged

within one minute.

A

If the purging was insufficient, the engine stops right

after starting. In this case repeat steps 2 to 3 again.

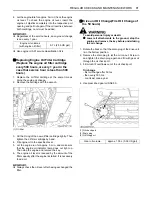

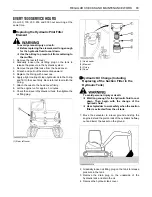

ADJUSTMENT OF TRACKS

C

To loosen the tracks, follow the following

procedure:

To avoid personal injury or death:

A

Do not loosen the grease fitting completely or

too quickly. Otherwise grease under high

pressure in the tension cylinder could squirt

out.

A

Do not crawl under the excavator.

1. Loosen the bolts and remove the cover.

2. Using a socket wrench, loosen the grease fitting a few

turns.

3. When grease oozes out from the thread, rotate the

track and loosen the track in the lifted position (see

illustration).

After adjustment is completed:

Using the socket wrench, tighten the grease fitting.

Tightening torque must be between 98 to 108 N-m (72.3

to 79.7 ft-lbs).

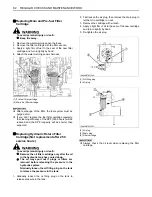

A

If the tracks are too tight, wear is increased.

A

If the tracks are too loose, the track pads may collide

with the sprocket and wear is increased.

The track may dislocate or come off.

A

Clean the track after every use.

A

Should the track tension be high due to sticking mud,

lift the track with the help of the boom, arm and bucket,

idle the engine and remove mud from the track by

rotating it.

C

Tense the tracks as specified:

1. Loosen the bolt and remove the cover.

2. Apply grease to the grease fitting.

3.

Rubber Tracks

Tense the track in the lifted position, so that the

distance "A" (clearance between the track roller and

the inside surface of the track) see illustration, in this

case, if there is a seam mark "

" on the inside

surface of the track, the seam mark "

" is positioned

on the top center between the idler and the sprocket.

Steel Tracks

To check the track tension, the track must be lifted

from the ground as shown. The track tension is correct

if the clearance between the outer end of the track

roller and the track interior surface corresponds to the

dimension specified in the table below.

(1) Starter switch

(A) "STOP"

(B) "RUN"

(C) "START"

(1) Cover

(2) Bolt

(3) Grease fitting

(4) Grease gun

Summary of Contents for KX080-4S

Page 10: ......

Page 18: ...SAFE OPERATION 8 ...

Page 19: ... 9 SAFE OPERATION ...

Page 20: ...SAFE OPERATION 10 ...

Page 21: ... 11 SAFE OPERATION ...

Page 22: ...SAFE OPERATION 12 ...

Page 23: ... 13 SAFE OPERATION ...

Page 26: ...DEALER SERVICE 2 1 Engine serial No ...

Page 71: ...47 EXCAVATOR OPERATION ...

Page 130: ...106 LIFTING CAPACITY ...