Caution

Caution

Caution

Caution

Caution

Caution

Caution

Caution

Caution

RPH

11

Then fill the reservoir of the constant-level oiler with oil and snap

it back into operating position. Screw vent plug in again. After

a short time check whether the oil level in the reservoir has

dropped. It is important to keep the reservoir properly filled at all

times!

If access to the vent plug is difficult or impossible, e.g. in cases

where the motor is arranged above the pump (piggy-back

arrangement), the oil can be filled in through the connection

elbow of the constant-level oiler.

The oil level shall always be below the level of

the vent opening arranged at the top edge of

the connection elbow.

During pump standstill the oil level can be checked at the oil

level sight glass.

6.1.2

Shaft seal

The mechanical seal has been fitted prior to

delivery. On variants with quench supply tank,

the tank must be fitted in accordance with the general

arrangement drawing (see also 6.1.3). Quench feed must also

be provided during pump shutdown. On variants with

pressurized dual mechanical seals, apply barrier pressure as

specified in the general arrangement drawing prior to starting

up the pump (see 6.1.3). Barrier pressure must also be provided

during pump shutdown.

For external liquid supply, the quantities and

pressure specified in the data sheet and

general arrangement drawing shall be applied.

6.1.3

Priming the pump and checks to be carried out

Before start-up, the pump, suction line and thermosyphon

vessel, if any, must be vented and primed. The shut-off valve in

the suction line must be fully open.

Fully open all auxiliary lines provided (flushing, barrier, cooling

liquid, etc.) and check the throughflow.

For water cooling, use suitable non-aggressive cooling water

not liable to form deposits and not containing suspended solids.

(Hardness: on average 5dH; (

~

1 mmol/l); pH > 8, or conditioned

and neutral with regard to mechanical corrosion).

Inlet temperature t

E

= 10 to 30

°

C

Outlet temperature t

A

max. 45

°

C

Dry running of the pump will result in

mechanical seal failure and must be

avoided!

6.1.3.1 Cooling

In general, the shaft seal must be cooled if the

vaporization pressure of the fluid handled is

higher than the atmospheric pressure.

Depending on the fluid handled, the system pressure and the

mechanical seal material, the limit may change (example: hot

water).

6.1.3.1.1 Cooling of the pump

The casing cover, the bearing bracket and the casing support

on the baseplate can be cooled.

p

allow.

= 10 bar

p

test

= 15 bar

Cooling liquid quantities:

Fluid temperature [

°

C] Cooling liquid

quantities [m

3

/h]

Casing cover

< 250

0.3

Casing cover

< 400

0.6

Bearing bracket

200

1)

/ 250 bis 315

2)

0 2

Bearing bracket

> 315

3)

0.2

Support on

baseplate

> 250

0.2

1) For n = 3500 1/min and n = 2900 1/min in conjunction with triple bearing

assembly. In all other cases from 250

°

C!

2) Water cooling or fan impeller

3) Water cooling (and optional fan impeller)

The cooling liquid quantities indicated are based on

D

t = max

15

°

C.

6.1.3.1.2 Cooling of heat exchanger

For mechanical seals with product circulation the following

cooling liquid quantities must be provided for the heat

exchanger:

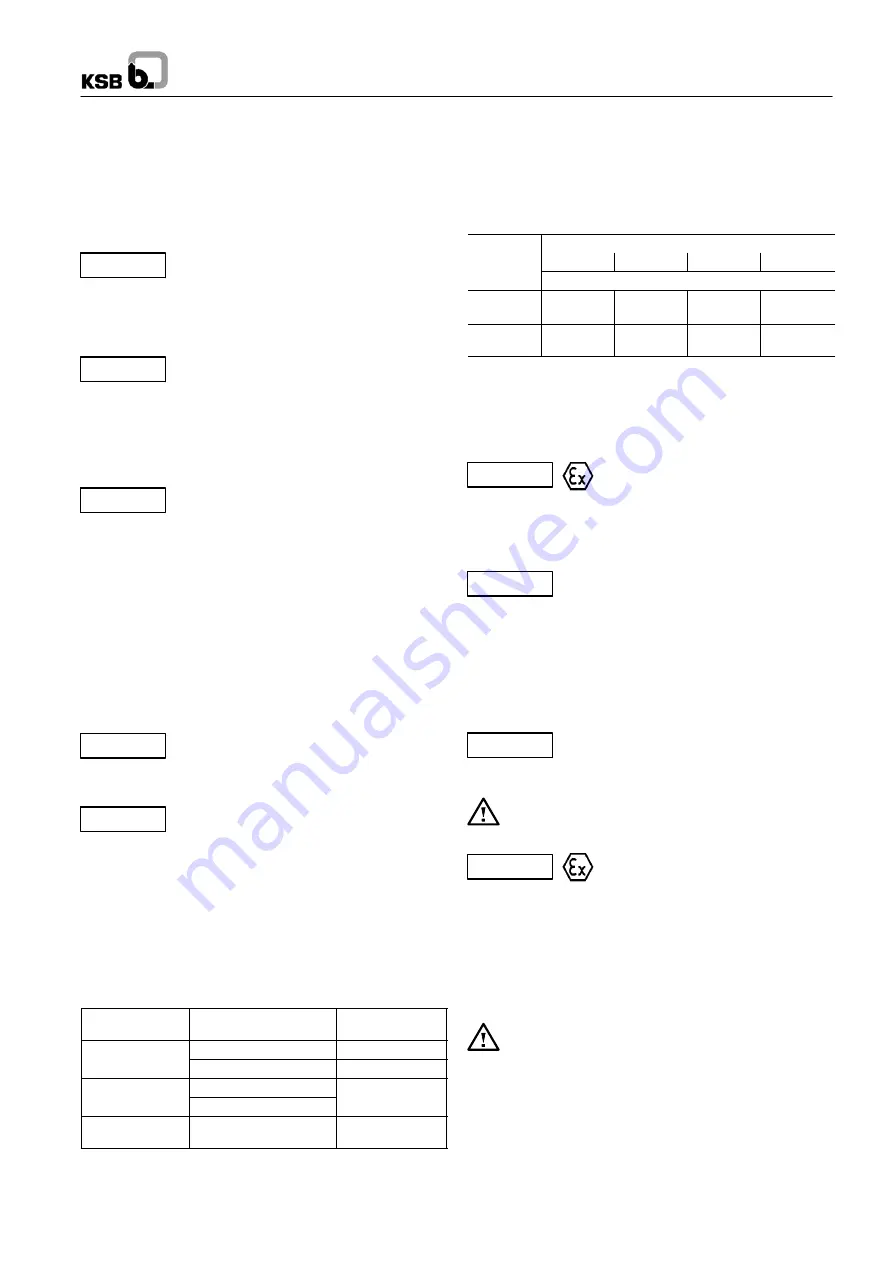

n=1/min

Bearing bracket

B 02

B 03

B 05

B 06

m

3

/h

1750/

1450

0.35

0.5

0.6

0.8

3500/

2900

1.2

1.2

1.8

-

Fig. 10

Cooling liquid quantity

6.1.3.2 Heating

The casing cover can be heated by feeding hot water or steam

(up to t = 150

°

C, p = 10 bar). In this case the casing cover is

sealed off with O-rings made of ethylene propylene.

Observe

permissible

temperature

classes.

6.1.4

Checking the direction of rotation

When the unit has been connected to the electric power supply,

verify the following (local and national regulations have to be

taken into account separately):

For trouble-free operation of the pump, the

correct direction of rotation of the impeller is of

paramount importance. If running in the wrong direction of

rotation, the pump cannot reach its duty point; vibrations and

overheating will be the consequence. The unit or the shaft seal

might be damaged.

Correct direction of rotation:

The direction of rotation must correspond to the direction

indicated by the arrow on the pump. Verify by switching the

motor on and then off again immediately.

On pumps fitted with inducers, the direction of

rotation must only be checked with the

pump/motor coupling removed, otherwise the inducer may

work loose and damage the pump.

Before checking the direction of rotation make sure that

there is no foreign matter in the pump casing.

Never hold your hands or any other objects into the pump!

Do not run the pump without liquid while

checking the direction of rotation! If it is

not possible to fill the pump, the direction of rotation must be

checked with the pump/motor coupling removed.

If the pump runs in the wrong direction of rotation, interchange

two of the three phases in the control cabinet or motor terminal

box.

The safety instructions set forth in section 2.9.3 must be

complied with.

6.1.5

Cleaning the plant piping

The cleaning operation mode and duration for flushing

and pickling service must be matched to the casing and

seal materials used.

6.1.6

Start-up strainer

If a start-up strainer has been fitted to protect the pumps against

dirt and/or to retain contamination from the plant, the strainer’s

contamination level must be monitored by measuring the

differential pressure so as to ensure adequate inlet pressure for

the pump.

For installation and monitoring, see additional instruction sheet.