13

7.4

Recommendations for installation

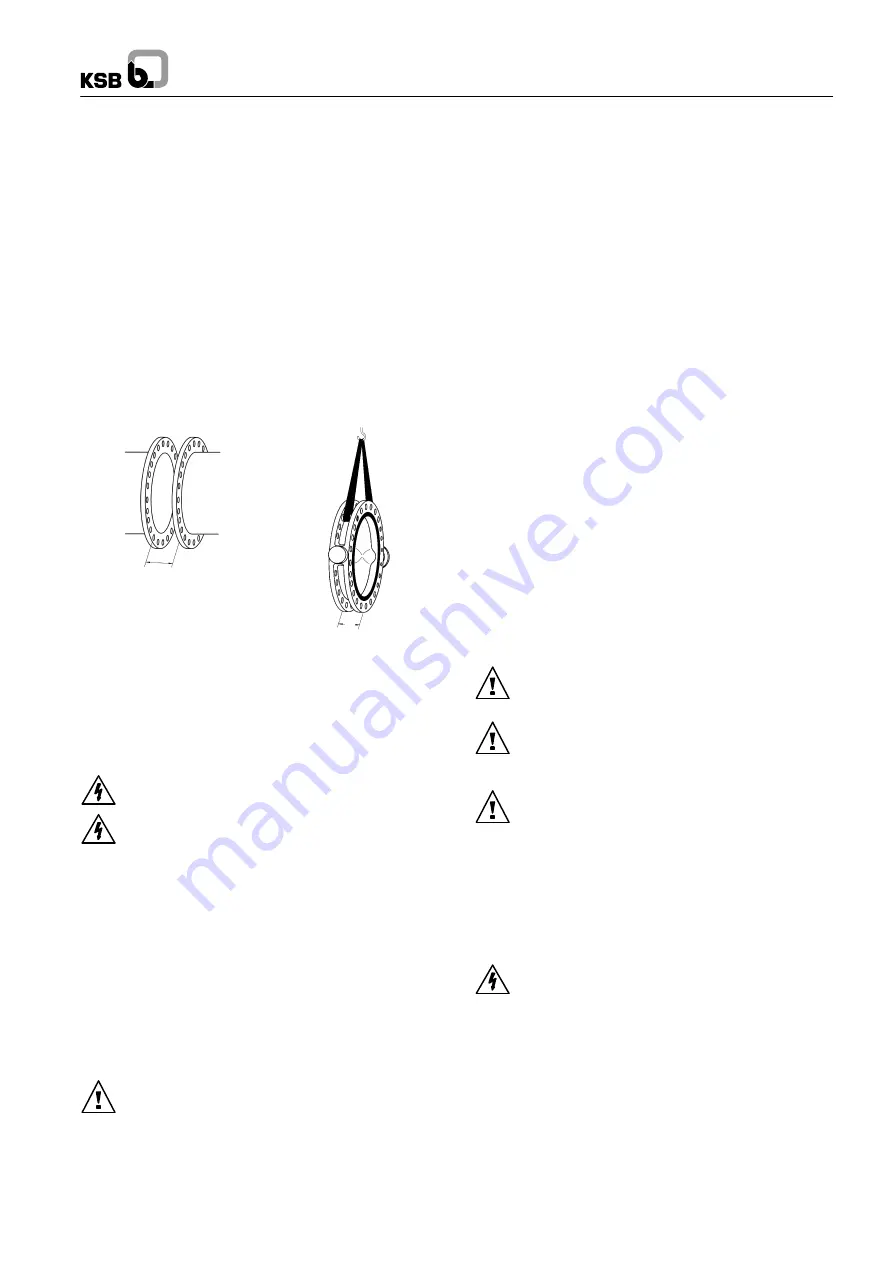

Before assembly

-- Verify that pipeline flanges are free from metallic chips and weld

splatter.

-- Verify that pipeline flanges are located on the same centreline and

are parallel.

-- Verify that inside diameter of pipeline flange is in accordance with

the minimum and maximum diameters given by the manufacturer.

-- Verify that nothing hinders the complete moving of the disc during

opening or closing, in particular at the internal weld seams or at the

pipe ends.

-- Pull apart the pipeline flanges to allow valve insertion without

damaging the elastomer liner of the valve.

During assembly

-- Place the disc as spaced apart as possible from the closing

position, but without that disc protrudes past the valve’s body.

-- Spread the two pipe flanges to obtain sufficient clearance between

flange face and valve seat cheeks.

E + 40 mini

E

Minimum clearance : E + 40mm

E : Face to face valve

(refer to the type series booklet)

-- Insert valve between pipeflanges and center using several tie--rods.

-- Screw up progressively the nuts until metal to metal contact is

achieved between the valve body and pipeline flanges, by making

sure the good centering of the body compared with the flange is

maintained.

-- Operate the valve several times to ensure no valve disc obstruction.

7.5

Actuated valves

Electrical cables may only be connected by qualified personnel.

The applicable electrical regulations (e.g. IEC and national

standards), also for equipment in hazardous locations, must be

observed.All electrical equipment such as actuator, switchboard,

magnetic valve drive, limit switch etc. must be installed in floodproof

dry locations.Voltage and frequency must match the valves stated on

the identity plate.

8

Commissioning/Decommissioning

8.1

Commissioning

8.1.1

General

Prior to commissioning the valve, the pressure, temperature and

material data stated on the valve should be compared to the actual

operating conditions in the piping system to check whether the valve

can withstand the loads occurring in the system.

Possible pressure surges (water hammer) must not be exceed

the highest admissible pressure. Adequate precautions should be

taken.In new pipe systems and especially after repair work, the

system should be flushed with the valves fully open to remove solids,

e.g. weld beads, which may damage the seats.

8.1.2

Operation

The position of the disc is indicated by the pointer of the actuator or by

handle lever. The valves are closed by turning in the clockwise

direction (top view) and opened in the counterclockwise direction.

8.1.3

Functional Check

The following functions should be checked:Before commissioning,

the shut-off-function of the valves should be checked by repeated

opening and closing.

8.1.4

Actuated valves

Adjustable end stops and torque limiter are pre--adjusted in factory.

The customer may have to complete the adjustment on site during the

commissioning, if necessary.

8.2

Decommissioning

During extended shutdown periods, liquids liable to change their

condition due to polymerization, crystallization, solidification etc. must

be drained from the piping system. If necessary, the piping system

should be flushed with the valves fully open.

9.

Maintenance/Repair

9.1

Safety Instructions

Maintenance and repair work may only be carried out by skilled and

qualified personnel.

For all maintenance and repair work, the safety instructions listed

below and also the general notes in section 2 must be

observed.Always use suitable spare parts and tools, even in case of

emergency, otherwise correct operation of the valves cannot be

assured.

9.2

Valve removal from piping and actuator

disconnecting

Identify the valve by identity plate.

Please check what is the relevant spare kit.

Place the disc at 10

°

opening.

The entire valve must be unpressurized and must have cooled

down sufficiently so that the temperature of the medium is lower than

60

°

C, to prevent scalding.

Opening pressurized valves will cause danger to life and

limb!lf toxic or highly flammable substances or liquids whose residues

may cause corrosion by interaction with the air humidity were handled

by the valve, then the valve should be drained and flushed or vented.lf

necessary, wear safety clothing and a face guard/mask.Depending on

the installation position, any liquid remaining in the valve may have to

be removed.

Prior to possible transport, the valves must be flushed and drained

carefully.lf you have any questions please contact your KSB Sales

Office.

lf actuators powered by an external source of energy (electric,

pneumatic, hydraulic) need to be removed from the valves or

dismantled, the energy supply must be shut down prior to starting any

repair work.

Remove the valve from the piping with its actuator.

Do not

damage the liner during removal the valve from the pipe. Therefore,

pull apart the pipe flanges to allow sufficient clearance.

Identify the mounting position of the actuator

Disconnect the actuator and take care of all bolting parts

.