LOADING AND SECURING

96

Operating instructions • Load Carrier • 505410638-02 • 07/2019

Fig. 8-3:

Strap ratchet

The straps are tensioned using suitable

clamping devices, such as strap ratchets or

lashing strap winches.

Lashing down the load

► Attach the hooks on the lashing belts

or lashing chains to the opening on the

lashing rail.

► Move the lashing belts to the required

position and allow them to engage

► Tighten the lashing belts.

ü

The load is lashed down.

8.2

Ensuring form-fitting

NOTE

Material damage caused by empty

spaces in the cargo area!

Empty spaces between parts of the cargo

can result in material damage to the load

while driving.

► Eliminate any empty space towards

the cargo space limiters.

► Eliminate any empty space between

individual pieces of cargo.

► Comply with the permissible axle load

when eliminating empty spaces.

► Fill empty spaces for example with

wooden pallets, storage pads or air

cushions.

► Fill stowage gaps in the middle with

packs of wood chip for example.

► Secure the load, e.g. by lashing it

down.

Flush loading and form-fitting makes load

securing easier. Form-fitting load securing

means that the load fills the space between

the load compartment limiters at the front,

side, and rear wall.

8.3

Securing pallets with hoop

casings and shrink-wrap

Fastening hoops and plastic foil shrink-

wrap of load items placed on pallets are

not intended for load securing. They only

fasten the load onto or with the pallet.

► Secure the load with hoop casings and

shrink-wrap on pallets against sliding,

e.g. by lashing it down

8.4

Load securing rail

KRONE trailers can be equipped with load

securing rails.

Load securing rails are used to attach ten-

sion straps, telescopic lock rods and tele-

scopic lock bars.

1

2

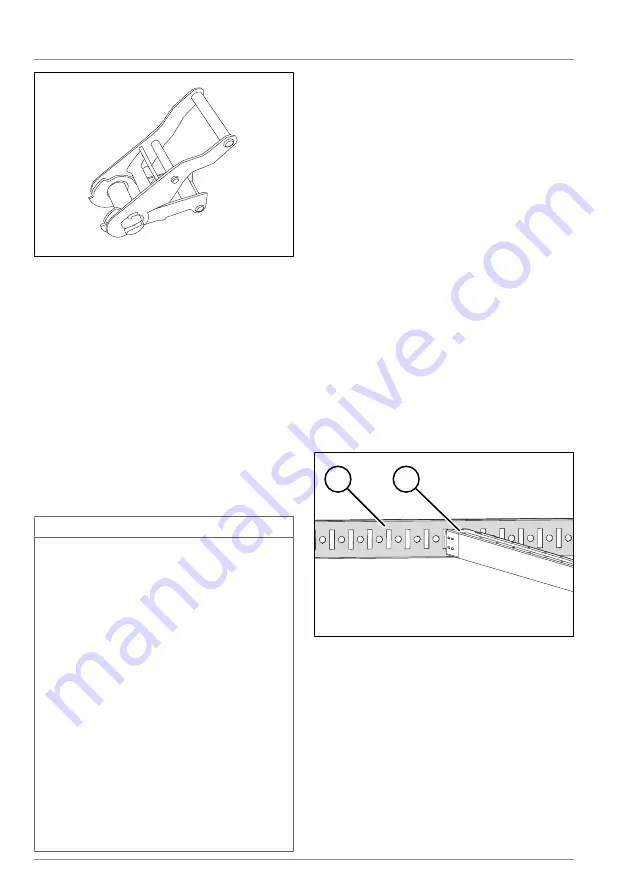

Fig. 8-4:

Load securing rails with telescopic

lock bars

1

Load securing rail

3

Telescopic lock bars

8.5

Securing the load with tele-

scopic lock rods

The load is secured against sliding with

telescopic lock rods. The telescopic lock

rods are equipped with spring-loaded slid-