Installation and operating instructions

6 BATCHFLUX

Part A System installation and start-up

1 Installation in the pipeline

1.1 Important

information

The following recommendations should be observed to ensure proper functioning of the

flowmeter – PLEASE NOTE.

•

Measuring tube must be completed

filled at all times.

•

Direction of flow:

the red arrow on the

housing of the primary head must point in

the direction of flow. If for structural

reasons the flowmeter can only be installed

counter to the direction of flow, the direction

of flow measurement can be

reprogrammed.

•

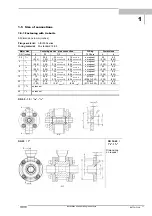

Stud bolts and nuts:

to fit, make sure

there is sufficient room next to the pipe

flanges.

•

Vibration:

support the pipeline on both

sides of the flowmeter. Vibration level to

IEC 068-2-34: below 2,2g in the

20 - 2000 Hz frequency range.

•

Radiant heat:

avoid e.g. from hot product

tanks, insulate if necessary.

•

Avoid strong electromagnetic fields

in vicinity of flowmeter.

•

Straight Inlet run

≥

5 x DN and straight

outlet run

≥

2 x DN, measured from the

electrode axis (DN = meter size).

•

Vortex or corkscrew flow:

increase

length of inlet and outlet runs or install flow

straighteners.

•

Mixing different process liquids:

install

flowmeter upstream of mixing point or at an

adequate distance downstream, minimum

of 30 x DN (DN = meter size), otherwise

display may be unsteady.

•

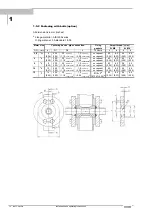

Plastic pipes and internally coated metal

pipes:

grounding rings required, see

“Grounding“, Section 1.3.3.

•

Heat-insulated pipelines:

do not insulate

flowmeter.

•

Zero setting:

not required. For checking

purpose, see Section. 7.1, it should be

possible to set “zero“ flow velocity in the

completely filled measuring tube. Shutoff

valves should therefore be provided either

downstream or upstream and downstream

of the flowmeter.

•

Ambient temperature

-25°C to +60°C

•

Process temperature

max. 140 °C

•

Transport and storage temperature

-25°C to +60°C

Limits imposed by the material

used for the

measuring tube for process temperature,

thermal shock limit, pressure and vacuum, see

Section 10.2 “Limits“.

Please note!

The ceramic measuring tube must not contact

metal parts (flange, pipeline). This can destroy

the flowmeter!

1