AS 72 S

English

11

Drilling

When drilling steel, take care that no swarf

enters the ventilation slits of the housing, as

these are attracted by the permanently active

magnet of the motor and would remain on the

motor.

Screwing

Inserting the screwdriver bits

The working spindle of the cordless screwdriver is

fitted with a hexagonal recess. After removing the drill

chuck, commercially available screwdriver bits with a

hexagon dimension of 6.3 mm or 1/4" according to

DIN 3126 Form C, can be used for facilitating the

screwing procedure by inserting directly into the work-

ing spindle:

– Turn rotational direction switch

3

to the “Lock” posi-

tion.

– Insert the bit.

Make sure that the bit and screw correspond in size

and shape.

It is advisable to use socket-head screws since their

self-centering action ensures safe work.

Or even better – TORX screws and the corresponding

bits. Optimal screwing is achieved when the screwing

device is fixed securely in the screw head.

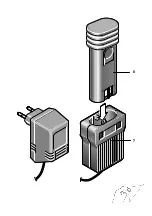

Bit garage

The bit garage can accommodate up to three bits. Pull

the bit garage

2

forwards and flap downwards. To

close the bit garage, flap upwards, push in fully and

notch.

Dismounting the Drill Chuck

Rotational direction switch in the LOCK

position

p

.

The drill chuck can then be loosened by lightly striking

a Allen key clamped in the drill chuck and screwed off.

Remounting takes place in the reverse order.

Clean the flat surfaces on the drill chuck and spindle

before mounting. Tighten the drill chuck again firmly

(at least 30 Nm).

Observe in addition that, when using a rim gear drill

chuck, the chuck key must not be attached to the

machine with chains, cords or similar means.

When drilling or screwdriving, secure the work

pieces against being rotated by the drill.

Servicing Instructions

If you make heavy use of the equipment for an

extended period of time, we recommend returning it

together with the charger to our servicing department

for a thorough inspection at regular intervals. This pre-

vents high repair costs and extends the service life of

your equipment.

Kress takes back worn-out machines

for the purpose of resource-saving

recycling. As a result of their modular

construction, Kress machines can be

very easily dismantled into their reusa-

ble materials.

Defective

rechargeable

batteries must

be recycled

according to the

Guidelines

91/157/EEC.

Do not throw

used batteries in

household waste,

in fire or in water.

Do not open battery and dispose of it through the

available collection points.

Do not place the battery on any heated surface or

expose it to strong sunlight for a longer period of time.

Do not expose the battery to temperatures over 50 °C.

Give your worn-out Kress machine to your dealer or

send it directly to Kress.

Subject to change without notice

8 Practical Tips

9 Maintenance Measures

10 Environmental Protection

Recycling

Akku

Summary of Contents for 12 04 0519

Page 2: ...7 6 ...

Page 3: ...6 1 2 3 4 5 ...