4

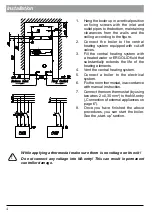

1. Hang the boiler up in a vertical position

on fixing screws with the inlet and

outlet pipes to the bottom, maintaining

clearances from the walls and the

ceiling according to the figure.

2. Connect the boiler to the central

heating system equipped with cut-off

valves.

3. Fill the central heating system with

a treated water or ERGOLID fluid that

substantially extends the life of the

heating elements.

4. Vent the central heating system.

5. Connect a boiler to the electrical

system.

6. Fix the room thermostat, in accordance

with manual instruction.

7. Connect the room thermostat (by using

two wires 2 x 0,35 mm

2

) to the NA entry

(„Connection of external appliances on

page 6”).

8. Once you have finished the above

procedures, you can start the boiler.

See the „start-up” section.

!

While applying a thermostat make sure there is no voltage on its exit!

Do not connect any voltage into NA entry! This can result in permanent

controller damage.

e

e

4 0 5 0 6 0 7 0 8 0

4 5 5 5 6 5 7 5 8 5

O

C

Return Inlet

Flow Outlet

Return Inlet

Flow Outlet

Installation