E-8

Adjusting the vertical punch position

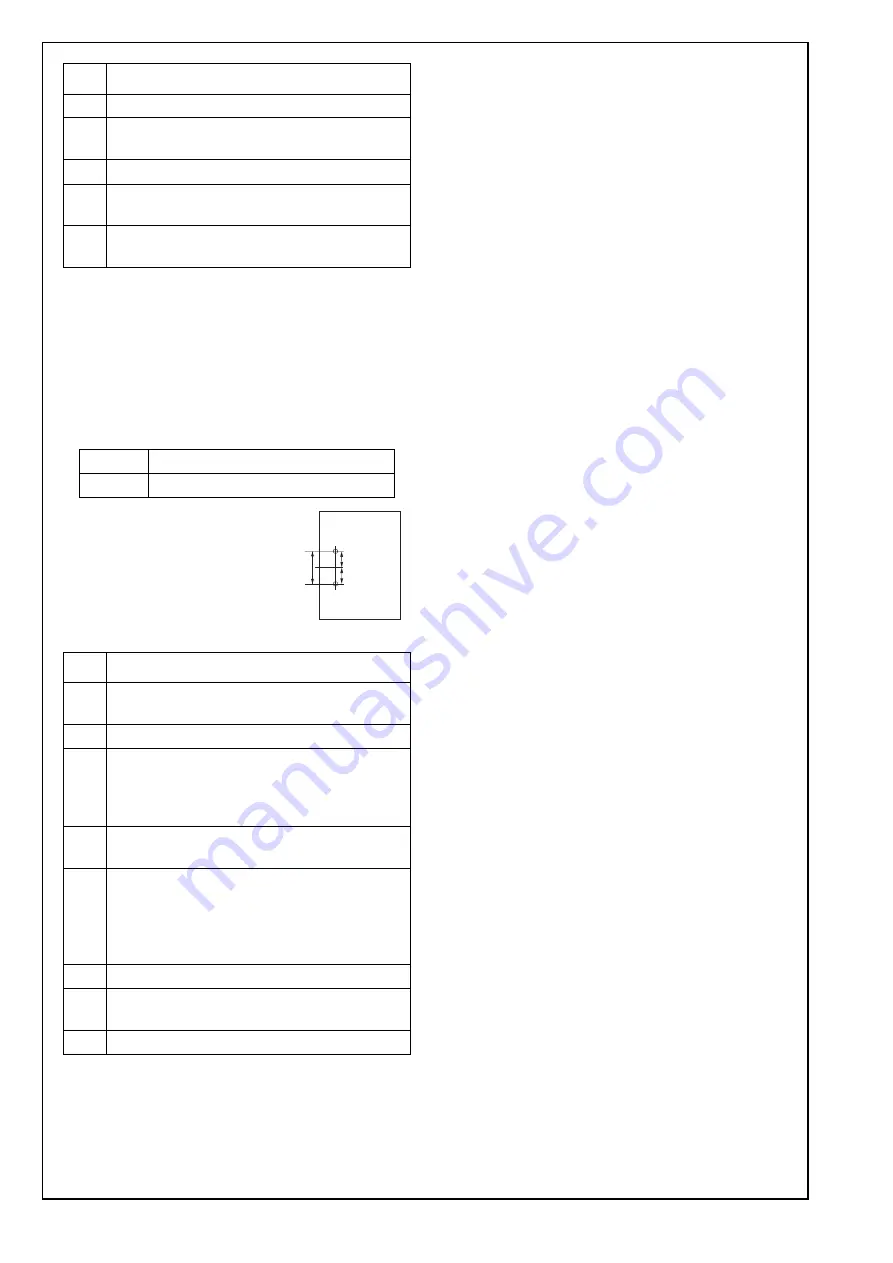

1. Standard value

• It is possible to adjust the B dimension of half of

the top and bottom by ±5mm from the standard

value.

• It is not possible to adjust the B value of the dis-

tance between holes.

Standard hole position

2. Adjustment procedure

6. Make another sample copy.

7. Repeat steps 3 to 6 until the punch registra-

tion size of PI1 tray is appropriate.

8. Place paper in the PI2 tray.

9. Repeat steps 3 to 6 until the punch registra-

tion size of PI2 tray is appropriate.

10. Touch “Return” to return to the [Punch Adjust-

ment Menu] screen.

B

Top and bottom center gap

80

±

0.5 Top and bottom B dimension 1/2

±

1

Step

1. [Punch Adjustment Menu screen]

Touch “Vertical Position Adj.”.

2. Select the paper size to be adjusted.

3. Touch “COPY” to display the Copy Screen.

Load the paper of size to be adjusted on the

tray, make a sample copy. Check the punch

vertical position of the sample copy.

4. Touch “SERVICE” to return to [Punch Adjust-

ment <Vertical position adjustment> screen].

5. If the punch vertical position is not appropri-

ate, use the numerical keys on the screen to

enter adjusting values (appropriate values),

and touch “<<SET”.

(Setting range: -50 to +50 1 step = 0.1mm)

6. Make another sample copy.

7. Repeat steps 3 to 6 until the punch vertical

position is appropriate.

8. Repeat the same operation about other sizes.

Step

B

15KNIXC008SA