3. Other

Field Service

V

er. 1.0 Dec. 2007

12

PF-505

Maintenance

3.3.6

Media feed clutch (CL1)

1.

Remove the Lower Feeder Unit.

2.

Remove the rear cover.

3.

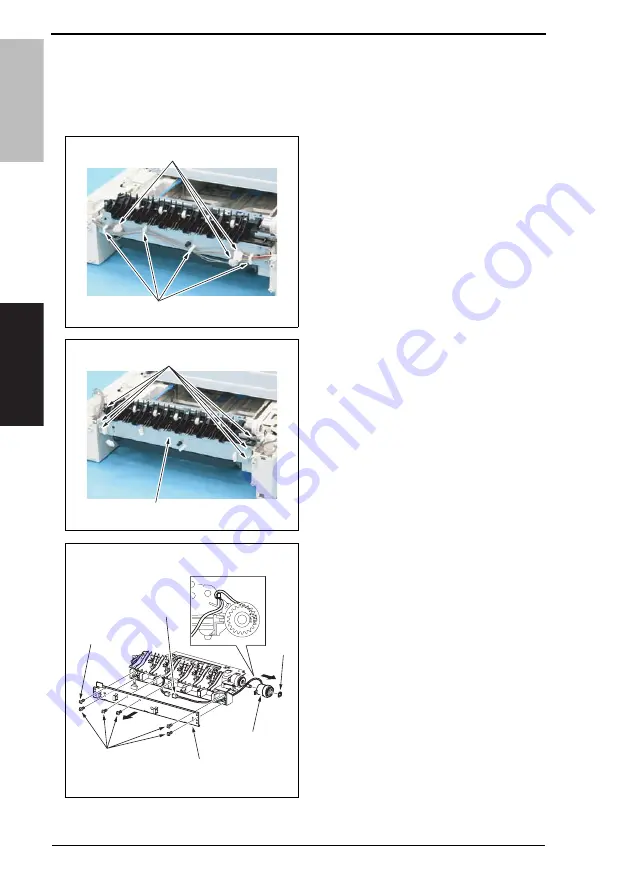

Disconnect three connectors [1] and

remove the harness from four wire

saddles [2].

4.

Remove six screws [1], and remove

the media feed unit [2].

5.

Remove six screws [1], and remove

the sheet metal [2].

6.

Disconnect the connector [3] and

remove the E-ring [4], and remove

the media feed clutch [5].

A0FGF2C004DA

[2]

[1]

A0FGF2C005DA

[2]

[1]

A0FGF2C514DA

[2]

[5]

[4]

[3]

[1]

[1]

Summary of Contents for bizhub 40p

Page 1: ...SERVICE MANUAL 2 2 20 0 00 0 07 7 7 1 1 12 2 2 V V Ve e er r r 1 1 1 0 0 0 FIELD SERVICE...

Page 3: ...ii Blank Page...

Page 23: ...MEASURES TO TAKE IN CASE OF AN ACCIDENT S 20 Blank Page...

Page 26: ...SERVICE MANUAL 2007 12 Ver 1 0 FIELD SERVICE Main body...

Page 183: ...12 Other functions Field Service Ver 1 0 Dec 2007 148 bizhub 40P Adjustment Setting Blank Page...

Page 229: ...18 Wiring diagram Field Service Ver 1 0 Dec 2007 194 bizhub 40P Appendix Blank Page...

Page 230: ...SERVICE MANUAL 2007 12 Ver 1 0 FIELD SERVICE...

Page 233: ...PF 505 General Maintenance Troubleshooting Field Service Ver 1 0 Dec 2007 ii Blank Page...

Page 253: ...4 Jam display Field Service Ver 1 0 Dec 2007 20 PF 505 Troubleshooting Blank Page...

Page 254: ...SERVICE MANUAL 2007 12 Ver 1 0 FIELD SERVICE...

Page 257: ...AD 508 General Maintenance Troubleshooting Field Service Ver 1 0 Dec 2007 ii Blank Page...

Page 259: ...1 Product specifications Field Service Ver 1 0 Dec 2007 2 AD 508 General Blank Page...

Page 275: ...4 Jam display Field Service Ver 1 0 Dec 2007 18 AD 508 Troubleshooting Blank Page...

Page 276: ...SERVICE MANUAL 2007 12 Ver 1 0 FIELD SERVICE...

Page 279: ...SF 603 General Maintenance Troubleshooting Field Service Ver 1 0 Dec 2007 ii Blank Page...

Page 281: ...1 Product specifications Field Service Ver 1 0 Dec 2007 2 SF 603 General Blank Page...

Page 291: ...3 Other Field Service Ver 1 0 Dec 2007 12 SF 603 Maintenance Blank Page...

Page 297: ...THEORY OF OPERATION SERVICE MANUAL 2007 12 2007 12 Ver 1 0 Ver 1 0...

Page 299: ...ii Blank Page...

Page 319: ...MEASURES TO TAKE IN CASE OF AN ACCIDENT S 20 Blank Page...

Page 322: ...SERVICE MANUAL 2007 12 Ver 1 0 Main body THEORY OF OPERATION...

Page 333: ...5 Image creation process Theory of operation Ver 1 0 Dec 2007 8 bizhub 40P Outline Blank Page...

Page 358: ...SERVICE MANUAL 2007 12 Ver 1 0 THEORY OF OPERATION...

Page 361: ...AD 508 Outline Composition Operation Theory of operation Ver 1 0 Dec 2007 ii Blank Page...

Page 363: ...1 Product specifications Theory of operation Ver 1 0 Dec 2007 2 Outline AD 508 Blank Page...

Page 368: ...SERVICE MANUAL 2007 12 Ver 1 0 THEORY OF OPERATION...

Page 371: ...PF 505 Outline Composition Operation Theory of operation Ver 1 0 Dec 2007 ii Blank Page...

Page 379: ...4 Operations Theory of operation Ver 1 0 Dec 2007 8 PF 505 Composition Operation Blank Page...

Page 380: ...SERVICE MANUAL 2007 12 Ver 1 0 THEORY OF OPERATION...

Page 383: ...SF 603 Outline Composition Operation Theory of operation Ver 1 0 Dec 2007 ii Blank Page...

Page 385: ...1 Product specifications Theory of operation Ver 1 0 Nov 2007 2 Outline SF 603 Blank Page...

Page 391: ...4 Operations Theory of operation Ver 1 0 Dec 2007 8 SF 603 Composition Operation Blank Page...

Page 393: ...PARTS GUIDE MANUAL JUNE 2010 bizhub 40P A0DX013...

Page 397: ...bizhub 40P DIAGRAM OF MAIN PARTS SECTION...

Page 416: ...DRIVE SECTION P 9 Please refer Page 10 Key 7 for parts described as S or E M1 1 2 bizhub 40P...

Page 424: ...PF 505 P 13 Please refer Page 10 Key 7 for parts described as S or E 1 2 3 bizhub 40P...