8

11

9

10

A

8

- 22 -

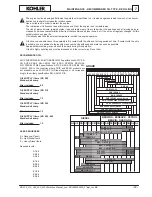

DISASSEMBLY/REASSEMBLY

Never clean the filtering element

6

using solvents with a low

flash point. This could cause an explosion !

Make sure that the retention rings

4 - 5

are in a good condition

and replace them if they are damaged.

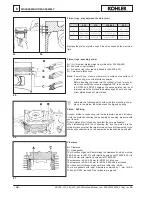

Oil-bath air cleaner (optional)

Components:

1

Upper shell

1A

Upper unit with separator pre-filter

2

Secondary filter element

3

Primary polyurethane

4

Internal seal ring

5

External rubber gasket

6

Lower metal filter element

7

Lower cup

8

Oil level gauge

Characteristics of filter element 2

:

made of Viledon synthetic fabric, porosity 120 gr/m

2

, resin-covered.

Characteristics of filter element 3

:

open-celled polyurethane foam; porosity 45 P.P.I..

Both filter elements can be washed with soap and water for a maxi-

mum of 10 times.

Wash the metal filter

6

with Diesel fuel Blow out excess fuel with com-

pressed air. See pages 14 and 15 for periodic maintenance details

and oil replacement.

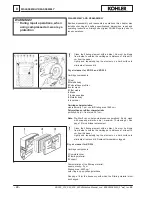

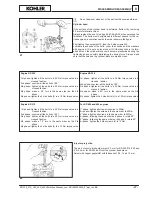

Allow the exhaust manifold to cool before demounting it in order

to prevent scorching and burns.

Muffler

When reassembling replace the exhaust manifold gaskets.

Tighten nuts to 25 Nm.

The muffler design includes internal sound absorbing panels.

Tighten the bearing nuts and screw

A

to a 25 Nm torque value.

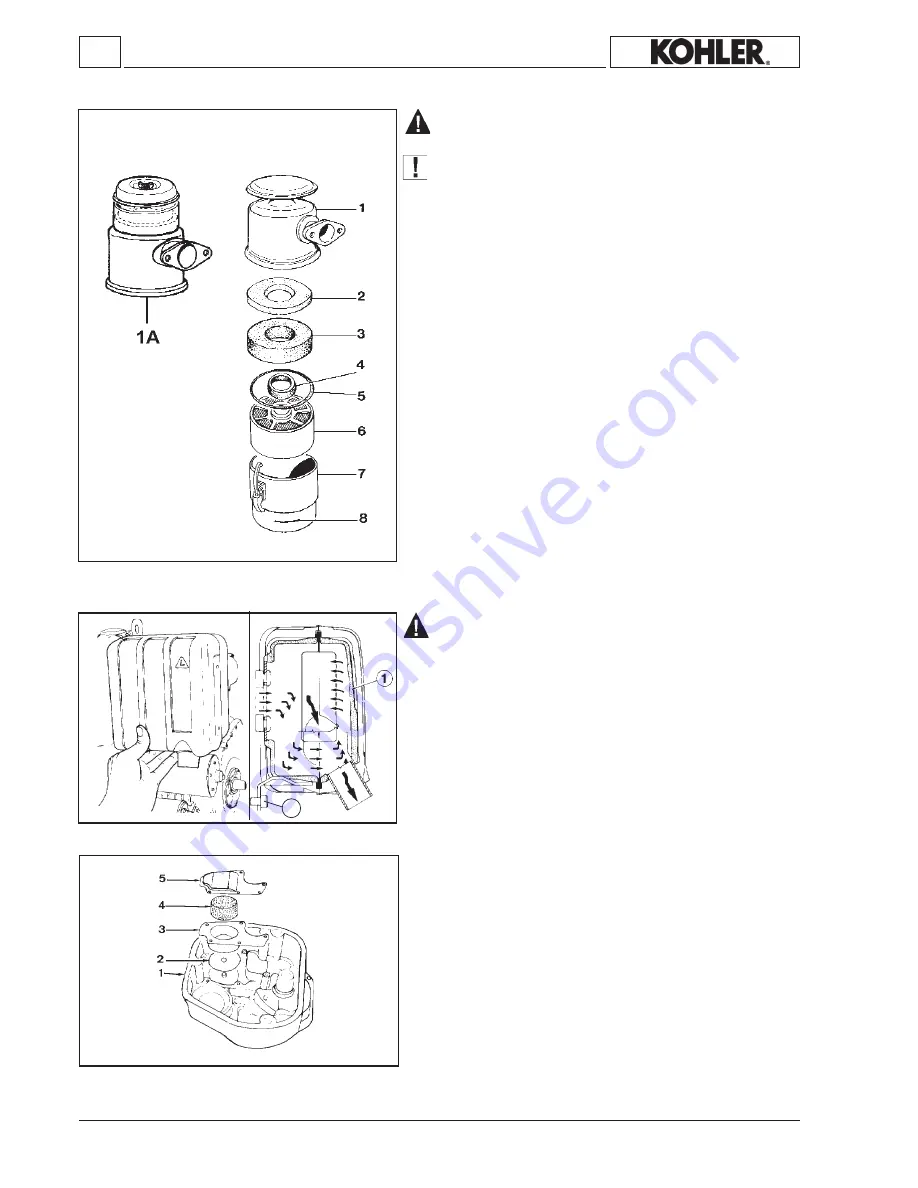

Rocker arm cover breather system

The crankcase breather system is located inside the rocker arm cover.

Check that diaphragm

2

is intact ; wash with Diesel oil and blow throu-

gh the small mesh element

4

with compressed air.

When reassembling fix box

3

with Loctite " Form-a- gasket No. 6" and

screw plate

5

. Also see below.

KD 225_315_350_400_440 Workshop Manual_cod. ED0053029330_

1° ed

_ rev.

00