1

2

3

8

- 20 -

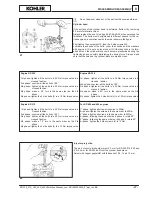

DISASSEMBLY/REASSEMBLY

WARNINGS!

During repair operations, when

using compressed air, wear eye

protection

.

DISASSEMBLY AND REASSEMBLY

Besides disassembly and reassembly operations this chapter also

includes checking and setting specifications, dimensions, repair and

operating instructions. Always use original KOHLER spare parts for

repair operations.

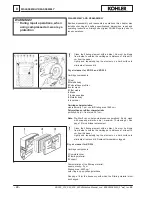

Clean the filtering element with air blast. Air must be blown

from inside to outside the cartridge at a distance of at least 15

cm from the paper.

Lightly and repeatedly tap the element on a hard surface to

eliminate all excess dirt.

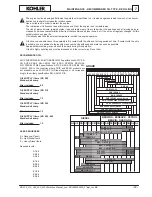

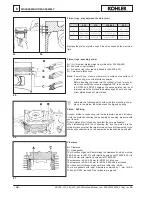

Cartridge components:

1

Seal

2

Metallic body

3

Polyurethane prefilter

4

outer mesh

5

Filter media

6

Blade

7

Inside envelope

8

Metallic body

9

Inner seal

Cartridge characteristics:

media porosity 7 µm, useful filtering area 1960 cm

2

.

Polyurethane pre-filter characteristic

:

porosity 60 p.p.i., front area 207 cm

2

.

Note:

Pre-filter

3

can undergo maintenance operations; if dirty, wash

with soap and water and dry ( maximum 10 cleanings ). See

page 18 for cartridge replacement.

Clean the filtering element with air blast. Air must be blown

from inside to outside the cartridge at a distance of at least 15

cm from the paper.

Lightly and repeatedly tap the element on a hard surface to

eliminate all excess dirt. Replace if irreparably clogged.

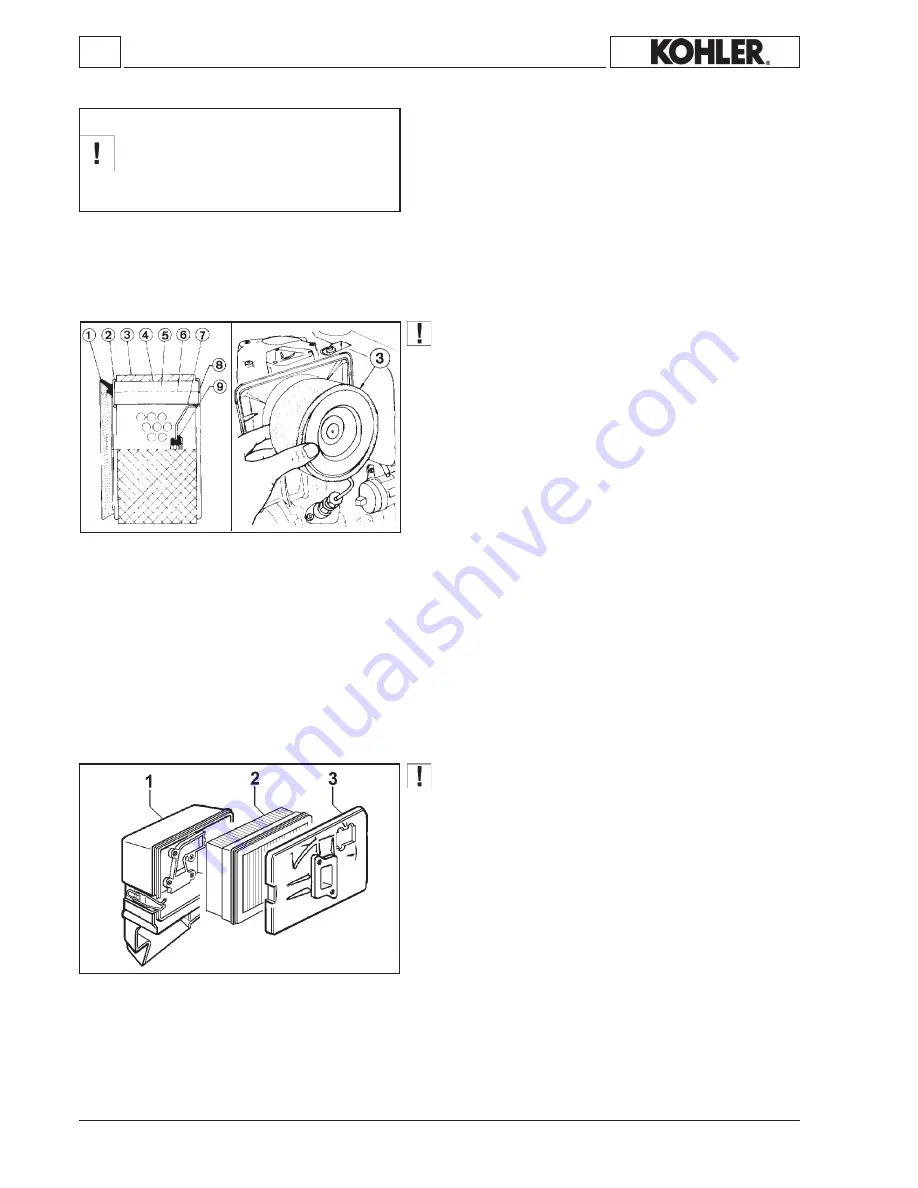

Cartridge components:

1

Complete cover

2

Filtering material

3

Support

Characteristics of the filtering material:

paper porosity : 3 µm

filtering area : 4400 cm²

outer ring in open-cell polyurethane

See page 18 for the frequency with which the filtering material must

be changed.

KD 225_315_350_400_440 Workshop Manual_cod. ED0053029330_

1° ed

_ rev.

00

Dry air cleaner for KD 315 and KD 350

Dry air cleaner for KD 225