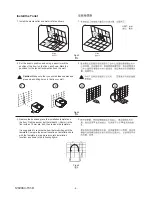

Notice: a. Because the installation position of the

sensor will affect directly to the future

operation of the sensor, you are

recommended to confirm the correction

position of the sensor after its placement

and fix it.

b. Don't mistake the direction of inlet and

outlet.

c. Don't drop the O-rings.

d. Keep the wire plug-in away from water.

e. Align the center of the flushing valve with

the center of the toilets/squats, and ensure

it parallel with the wall, or will result in the

false operation of the sensor.

f. Do not use any sealant or grease on the

valve or connector and outlet pipe.

g. While more than 3 sets of sensor were

installed in one lavatory, the inner diameter

of main inlet pipe should not be less than

38mm.

h. Do not connect the DC output of AC Power

unit to AC power supply.

i. Do not connect to power supply while

installing. Connection line is not supplied.

AC connection wire with insulating sleeving

is recommended. Wire of which the nominal

section area of conductor is not less than

0.5mm is also recommended. DC

connection line use wire of which the

nominal section area is not less than

0.3mm . It is cut according to acted

installation requirements(The length of cut

wire is recommended less than 10m).

j. The head AC power supply must be

protected with appropriate fuse.

k. Please confirm the AC power supply and

water supply should be shut off before

maintaining the products with AC power

related.

2

2

1350669-T01-A

6

a.

b.

c.

d.

e.

f.

g.

h.

i.

j.

k.

2

2

因为感应器的安装位置将对感应器的工作

产生直接影响,要求放置后经测量确认感

应器位置准确无误后再固定。

不要将进出水方向弄错。

不要将密封圈丢失。

不要让接插件受潮。

冲洗阀中心要求与座/蹲便器中心对齐并保

证与墙面平行,否则将可能引起误动作。

不要在阀体部件或接头和出水配管上使用

任何密封胶或油脂。

当一个卫生间同时安装

3

台以上感应器时推

荐主供水管内径大于

38mm

。

不可将交流电源盒的直流输出端与交流电

连接。

安装时不要向电源盒供电。连接线请用户

自备,建议交流电源线采用导体标称截面

积

0.5mm

的电线,直流连接线采用导体

标称截面积

0.3mm

的电线,电线长度根

据实际安装需要自行裁剪(建议连接线长

度小于

10m

)。

交流电的总电源必须有合适的熔断丝加以

保护。

维修时必须断开交流电源并关闭水源。

注意: