12

Check Spark Plug

Annually or every

100 hours

of operation, remove the

spark plug, check condition, and reset the gap or

replace with new plug as necessary. The original plug

is an NGK BPR4ES. The Champion

®

equivalent of that

NGK plug is RN14YC. The service replacement is

Champion

®

RC14YC (Kohler part No. 66 132 01-S).

Equivalent alternate brand plugs can also be used.

1. Before removing the spark plug, clean the area

around the base of the plug to keep dirt and debris

out of the engine.

2. Remove the plug and check its condition.

Replace the plug if worn or reuse is questionable.

NOTE: Do not clean the spark plug in a machine

using abrasive grit. Some grit could

remain in the spark plug and enter the

engine causing extensive wear and

damage.

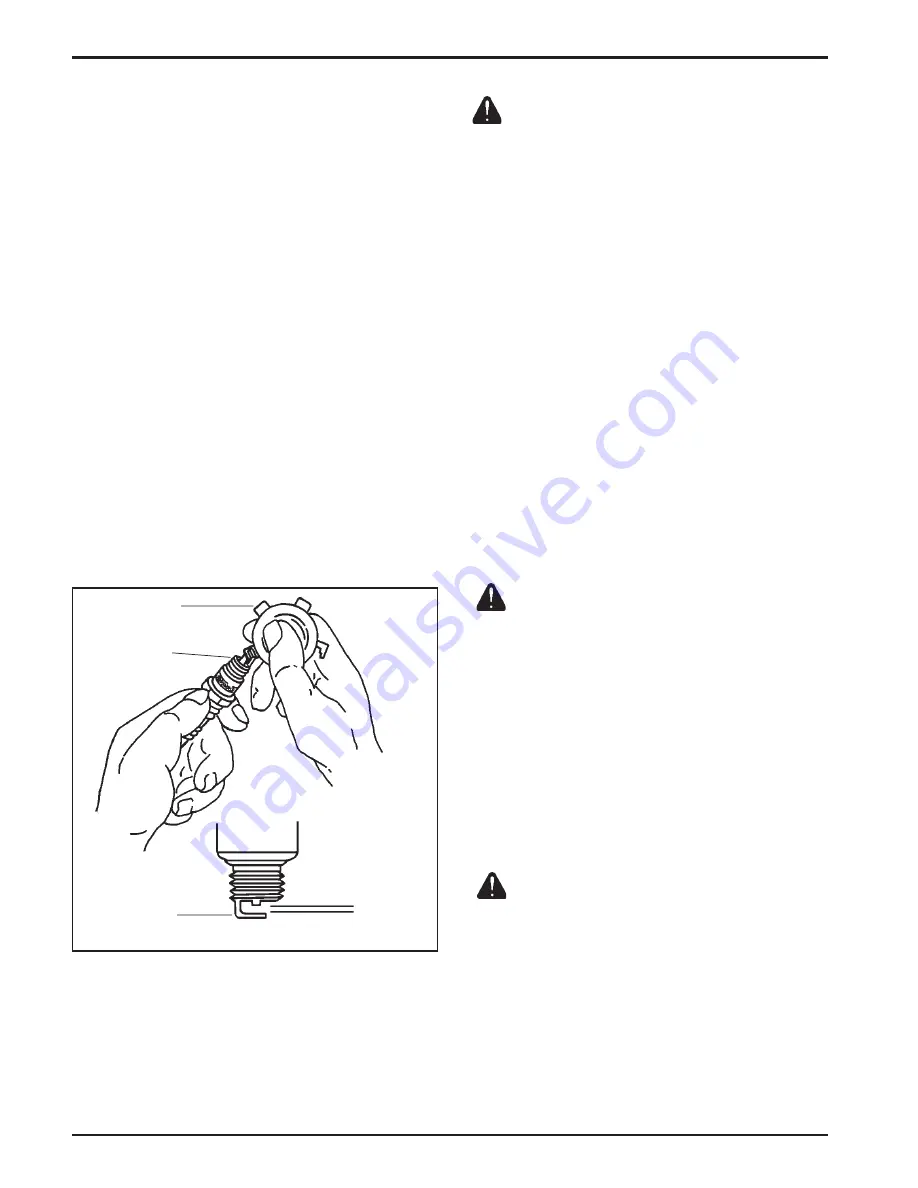

3. Check the gap using a wire feeler gauge. Adjust

the gap to

0.76 mm (0.030 in.)

by carefully

bending the ground electrode. See Figure 14.

4. Reinstall the spark plug into the cylinder head.

Torque the spark plug to

20 N·m (14 ft. lb.)

.

Ground

Electrode

Spark Plug

0.76 mm

(0.030 in.) Gap

Wire Gauge

Battery Charging

WARNING: Explosive Gas!

Batteries produce explosive hydrogen gas while being

charged. To prevent a fire or explosion, charge

batteries only in well ventilated areas. Keep sparks,

open flames, and other sources of ignition away from

the battery at all times. Keep batteries out of the reach

of children. Remove all jewelry when servicing

batteries.

Before disconnecting the negative (-) ground cable,

make sure all switches are OFF. If ON, a spark will

occur at the ground cable terminal which could cause

an explosion if hydrogen gas or gasoline vapors are

present.

NOTE: Do not apply 12 volt DC to kill terminal of

ignition module.

Fuel Valve

Engines are equipped with a fuel valve and integral

screen filter located at the outlet of the fuel tank. See

Figure 15. It controls and filters fuel flow from the tank

to the carburetor.

Every 100 hours of operation

clean filter screen and

cup of any accumulated debris as follows:

CAUTION!

Never use or be near fuel or solvent while smoking or

in the vicinity of an open flame.

1. Stop the engine.

2. Turn the fuel valve lever to

‘‘off.’’

3. Remove the fuel valve cup and gasket.

4. Clean the cup with solvent and wipe it off.

5. Check the gasket, replace if damaged.

6. Reinstall the gasket and fuel valve cup.

CAUTION!

Be sure the fuel valve cup is tightened securely.

Figure 14. Servicing Spark Plug.