7

3.

INSTALLATION

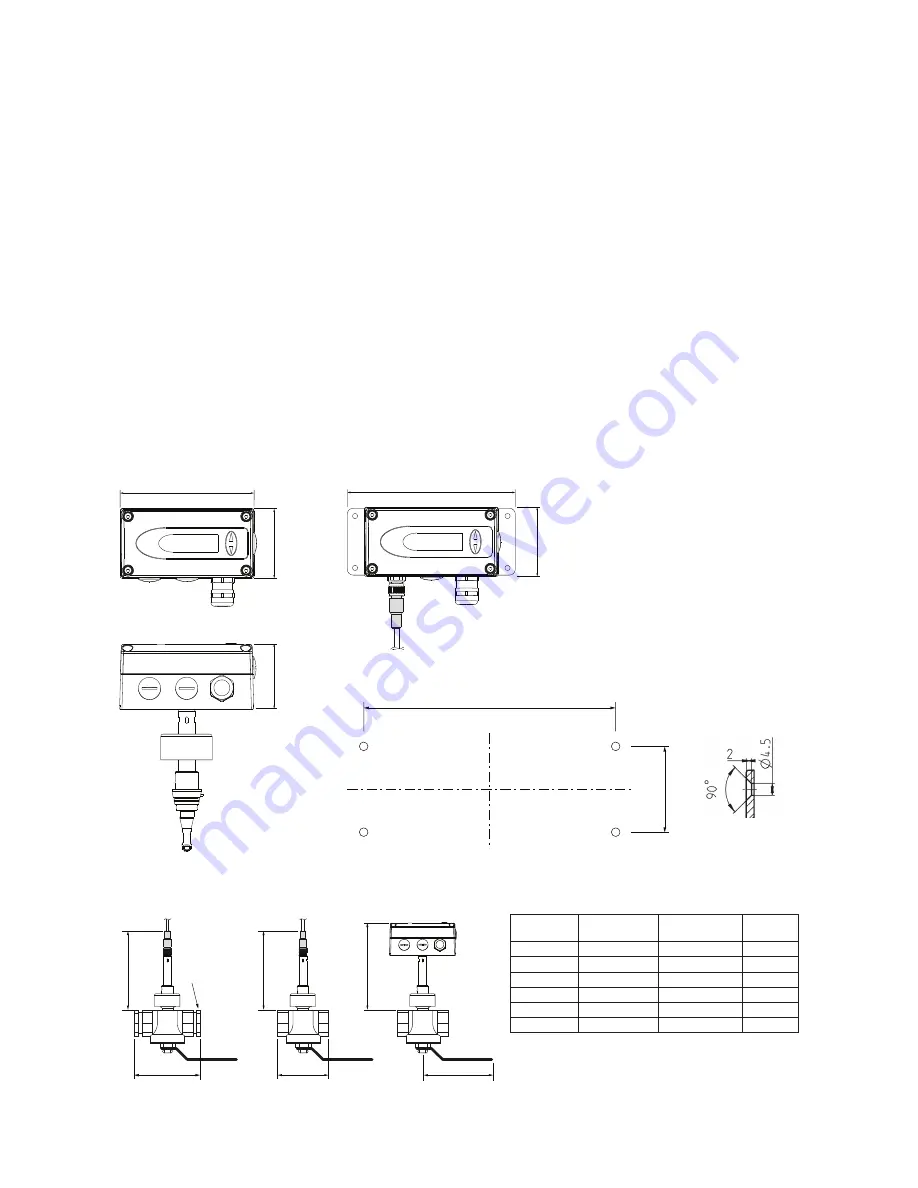

3.1. Mounting dimensions

3.1.1. KMT-1, KMT-2 and KMT-3

115

145

129

60

56

60

40

cable gland

M16x1.5

cable gland

M16x1.5

Cross-section

bore hole:

Drilling Plan:

The bottom part of the housing is mounted with

4 screws (not in the scope of supply)

Max. screw diameter: 4.5 mm (0.17 inch).

e.g. 4.2 x 38 mm DIN 7938H Screws

Measurement ball valve

Non-return protection for secure mounting

The patented non-return protection combines three functions in one device:

• Non-return protection

The sensor can only be pushed in one direction during installation. The sensor cannot return at all,

even if it is released.

• Seal

By means of an encapsulated O-ring, no compressed air can escape under pressure during assem-

bly.

• Precise positioning

The precise positioning with respect to immersion depth and orientation is easy to perform, guaran-

teeing accurate measurement results.

Mounting grip

With the mounting grip, the sensing probe is inserted and correctly positioned into the pipe line.

7

6

183

(7.2)

173

(6.81)

A

A

B

Only at DN15:

Reduction

3/4“-1/2“

173

(6.81)

Measurment

ball valve

Thread

A

B

DN15

R

p

1/2"

100±8

(3.94±0.32)

92

(3.62)

DN20

R

p

or NPT 3/4”

72

(2.83)

92

(3.62)

DN25

R

p

or NPT 1”

83

(3.27)

124

(4.88)

DN32

R

p

1 1/4"

100

(3.94)

124

(4.88)

DN40

R

p

or NPT 1 1/2"

110

(4.33)

147

(5.79)

DN50

R

p

or NPT 2”

131

(5.16)

147

(5.79)

dimensions in mm (inch)

Female thread: BSP thread acc. EN 10226 (old DIN 2999) or NPT

Summary of Contents for KMT-1

Page 36: ...www kobold com...