4

Knorr-Bremse Group

PD-203-360

Doc. No. Y250908 (EN - Rev. 001)

September 2016

The information contained herein is subject to alteration without notice and therefore may not be the latest release. Please check our website www.knorr-bremseCVS.com for the latest update or contact your local Knorr-Bremse representative.

The figurative mark “K” and the trademarks KNORR and KNORR-BREMSE are registered in the name of Knorr-Bremse AG. Additional terms and conditions apply; please refer to our website knorr-bremseCVS.com for full Disclaimer.

Note: If service work is carried out on a vehicle based on information provided herein, it is the responsibility of the workshop to ensure the vehicle is fully tested and in full

functional order before the vehicle is returned into service. Knorr-Bremse accepts no liability for problems caused as a result of appropriate tests not being carried out.

Copyright © Knorr-Bremse AG - all rights reserved, including industrial property rights applications. Knorr-Bremse AG retains any power of disposal, such as for copying and transferring.

Knorr-Bremse Systeme für Nutzfahrzeuge GmbH . Moosacher Straße 80 . 80809 Munich . Germany . Tel: +49 89 3547-0 . Fax: +49 89 3547-2767 . www.knorr-bremse.com . www.knorr-bremseCVS.com

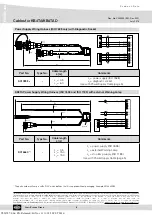

KB4TA/KB4TA D System Components

P r o d u c t D a t a

Load Sensing Valve

Valve for trailers with air suspension

Features:

The load sensing valve is used to modify the applied

service brake pressure in relation to the load imposed on

the vehicle’s axles. The air suspension load sensing valve

uses the pressure in the suspension air springs to “sense”

the load imposed on the axles and determine the valve’s

braking ratio.

Versions of the valve are available with or without relay and

emergency features, and with static or dynamic operation.

A static valve uses the load sensing ratio at the point of

brake application which remains constant throughout the

brake application while a dynamic valve continually adjusts

the load sensing ratio throughout the brake application

and therefore takes account of any load transfer.

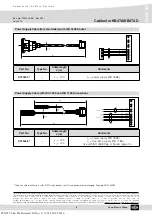

A trailer mounted data plate, showing the settings of the

load sensing valve is required by ECE Regulation 13 and

Directive 71/320/EEC.

Technical Data:

• Maximum operation pressure: . . . . . . . 8,5 bar

• Operating temperature range: . . . -40 °C to +80 °C

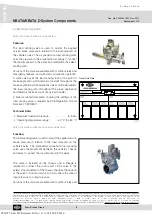

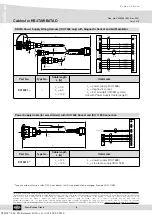

Valve for trailers with mechanical suspension

Function:

The load sensing valve is used to adjust the applied service

brake pressure in relation to the load imposed on the

vehicle’s axles. The mechanical suspension load sensing

valve uses the movement between the vehicle’s chassis

and axles to „sense“ the load imposed on the axles.

The valve is installed on the chassis and a linkage is

required to connect the control arm of the valve to the

axle(s). Any movement of the chassis changes the position

of the valve’s control arm which, in turn, alters the ratio of

input pressure to output pressure.

Versions of the valve are available with or without relay and

Trailer Data Plate

Y026787: 006: EN: Released: Fri Nov 11 11:18:50 CET 2016: