32

33

www.klimor.com

www.klimor.com

MCKT - SUSPENDED MODULAR AIR CONDITIONING AND VENTILATION UNITS

OPERATION AND MAINTENANCE MANUAL

6.10 Electric heater

The electric heater should be connected so as to pre-

vent switching on (operation) of the heater when the

fan is not in operation. The moment the fan is stopped,

heater operation should be stopped as well. Adjust-

ment degrees (1, 2 or 3) of the heater’s power output

are on the terminal strip from which supply wires

should run through stuffing boxes placed in the unit’s

ceiling.

Access to the terminal strip is possible after the inspec-

tion panel has been removed. The strip has got termi-

nals for connecting the neutral and earth wires and ter-

minals for the thermostat protecting against excessive

air temperature rise inside the heater (occurring as a re-

sult of an interruption or reduction of airflow). The ther-

mostat contacts, included in the heater supply control

circuit, open in air temperature close to the thermostat

ranging from 65 to 75ºC. When the temperature drops

by about 25K the thermostat contacts close. The heat-

er control circuit must be unconditionally fitted with

a thermostat. In order to guarantee safe maintenance

operations on the unit in the supply line, a mainte-

nance switch must be installed that allows disconnect-

ing power supply during power consumption. Should

it be necessary to remove the inspection panel of the

module with the motor or/and heater (maintenance,

failure), all supply circuits should be switched off.

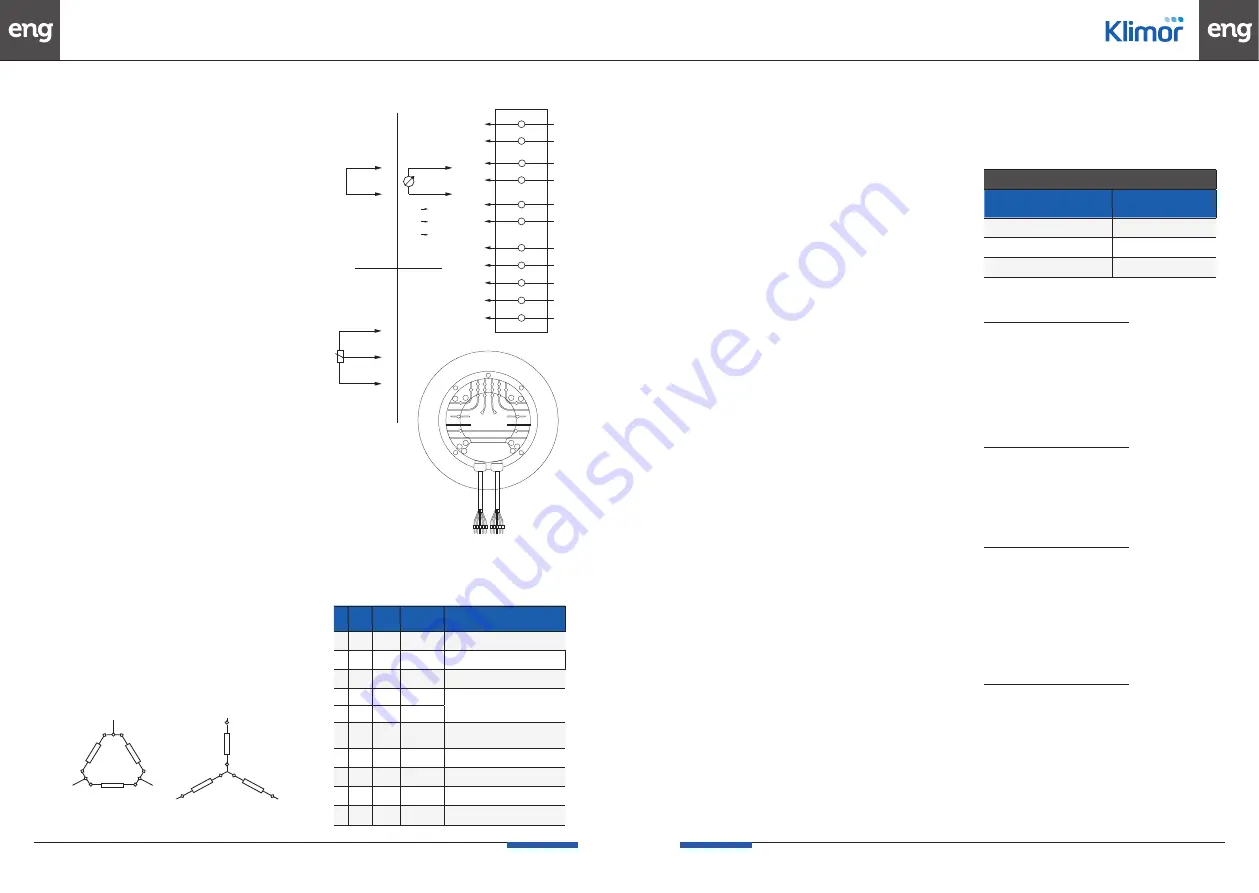

6.9 Fan Motor

The fans used in the units are powered by three-phase

squirrel-cage motors, whose revolutions can be easily

controlled by inverters. The recommended setting of

the inverters for the start-up/warm-up time of the fan

is a minimum of 30s. The engine should be powered in

accordance with applicable regulations and standards

and in accordance with data on the motor’s nameplate.

Connection should be done with the use of overload

and short circuit protection depending on the rated

current of the installed motor.

Before connecting the power supply, the diagrams be-

low should be checked for compliance with the data on

the motor’s nameplate.

In order to ensure safe maintenance operations, it is

necessary to install a maintenance switch in the fan

section to cut off power supply to the fan motor. The

switch should be installed within sight of the personnel

performing maintenance operations.

DRAWING 17:

Connection diagram of three-phase motor winding

DRAWING 18:

Connection diagram of

electric fan with built-in

EC motor (electronic

commutation).

In case of a fan with a built-in EC motor, control is done

according to DRAWING 18.

Table No. 5

Connection indication of fan with EC motor

No. Conn.

Destina-

tion

Color

Function

1

1, 2

PE

Green-Yellow

Protective earth

1

3

N

Blue

Power supply cable neutral

1

5

L

Black

Power supply cable phase

1

6

NC

White 1

State ralay: floating status contact,

break with error max 250 V / 2 A, min. 10 mA

1

7

COM

White 2

2

8

0-10V

Yellow

Analogue input 1 (set value);

0-10V; Ri=100kΩ;

2

10

RSB

Brown

RS485 interface for Modbus, RSB

2

11

RSA

White

RS485 interface for Modbus, RSA

2

12

GN

Blue

Reference ground for control interface SELV

2

13

+10V

Red

Fixed voltage 10 V +/-3%;

6.12 Heat Pump Module

Complete information about the power connection of

the heat pump module is available in OMM of control

system.

6.13 Control system

Since it is possible to use one of many control systems,

this manual does not include information regarding

the installation of automation elements, their start-up

and operation.

MCKT units are fitted with automation elements that

are installed inside the unit, i.e. antifreeze thermostat

for water heaters and thermostat preventing overheat-

ing in electric heaters. These elements have protective

functions only when cooperating with the appropriate

control system.

All information is included in OMM re. control system.

7. Preparing for First Start-up

Only appropriately qualified and trained installation and

start-up team can perform first start-up of the unit after the

ventilation or air conditioning installation has been com-

missioned.

It is a requirement that start-up be preceded by the follow-

ing operations:

• checking whether all the unit’s modules are connected

together and suspended correctly,

• checking whether the air installation has been con-

nected correctly and there are no leaks,

• checking hydraulic and Freon installations for leaks,

their readiness for work and whether the heating or

cooling medium is available at start-up,

• checking whether power connections are correct,

checking wiring and operational readiness of power

receivers,

• checking correct installation of traps and the system for

condensate drain from drip trays,

• checking correct installation of automation elements.

Moreover, it is necessary to clean the interior of unit casings

and ducts cooperating with them. One should also make sure

that the parts of the units, hydraulic installation and automa-

tion fittings have not been damaged during installation works.

7.1 Power Supply Installation

It should be checked whether power installation and

safeties of all power receivers have been connected

properly.

7.2 Filters

Remove protective foil from filters. Make sure the con-

dition of the filters is correct (leakproofness, fixing on

the tracks). Set the pressure switches correctly (if they

have been removed), determining the admissible final

drop of static pressure on the filter – when the drop

has been exceeded, it is recommended that the filter

be renewed.

The table presents the admissible pressure drop for the

filters used:

Table No. 6

Filter Type and Class

FILTER TYPE AND CLASS IN MCKT

Filter Type and Class

Admissible Pressure Drop

according to PN-EN13053:2008

Cassete Filter G1÷G4 (EU1-EU4)

150 Pa

Bag Filter M5÷F7 (EU5-EU7)

200 Pa

Bag Filter F8÷F9 (EU8-EU9)

350 Pa

7.3 Water Heaters

The following should be checked:

• condition of exchanger lamellas (mechanical damage,

contamination),

• correct connection of supply and return pipeline,

• fixing of antifreeze thermostat capillary, which should be

undone on the heater,

• set the antifreeze thermostat to +4°C,

• whether the exchanger is free of air.

7.4 Electric Heaters

The following should be checked:

• condition of electric heating elements of the heater, if

they are not damaged or are not in contact with the ele-

ments inside the heating module,

• correctness of power connections,

• correct connection of protective thermostat.

7.5 Water and DX cooling coils

The following should be checked:

• condition of exchanger lamellas (mechanical damage,

contamination),

• correct connection of supply and return pipeline,

• position of condenser with regard to airflow direction,

• correct fixing of the trap, trapping height and perme-

ability of the drain installation. Before start-up of the

unit the trap must be filled with water,

• whether the exchanger is free of air.

7.6 Cross-flow Counter-current Exchanger

The following should be checked:

• condition of exchanger lamellas (mechanical damage,

contamination),

• operation of the air damper mounted on the exchang-

er and bypass air damper,

• correct fixing of the trap, trapping height and perme-

ability of the drain installation. Before start-up of the

unit the trap must be filled with water.

• Check the mounting of the actuator on the bypass

damper and in the case of HPM on the actuator on

exchanger damper. Check the direction of acuator

rotation.

TRIANGLE CONNECTION

STAR CONNECTION

PE

PE

N

L

NC

COM

0-10V

RSB

RSA

GND

10V

CUSTOMER CIRCUIT

full speed

adjustable speed

with potentiometer

8

2

3

5

6

7

8

10

11

12

13

1

12

external

adjustable

speed signal

(0-10V)

FAN CIRCUT

8

+

_

13

1-10V

10V n=max

1 V n=min

<

1V n=0

13

8

10K

12

PE

PE

N

L

NC

COM

0-10V

RSB

RSA

GND

10V

CUSTOMER CIRCUIT

full speed

adjustable speed

with potentiometer

8

2

3

5

6

7

8

10

11

12

13

1

12

external

adjustable

speed signal

(0-10V)

FAN CIRCUT

8

+

_

13

1-10V

10V n=max

1 V n=min

<

1V n=0

13

8

10K

12