—

16

—

8.1.2 Load chain

Failure to maintain clean and well lubricated load chain will void the manufacturer’s warranty.

ALWAYS

lubricate load chain weekly, or more frequently, depending on severity of service.

ALWAYS

lubricate more frequently than normal in a corrosive environment.

(2)

ALWAYS

use machine oil equivalent to ISO VG46 or 68.

Note:

(2)

KITO has a corrosion-resistant chain as an option.

For information on KITO’s regular and corrosion-resistant chain, please ask KITO or

authorized KITO dealer.

8.2 Overhaul, assembly and adjustment

8.2.1 Overhaul

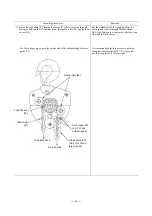

Figures in parentheses are Fig. No. in “PARTS LIST”. (Refer to page 27 to 32.)

To disassemble or reassemble the hoist, prepare for the following tools.

- External snap ring plier

- Internal snap ring plier

- Wrenches 10mm, 12mm, 13mm, 14mm, 17mm, 19mm

- Pliers

- Plastic hammer

Overhaul procedures

Remarks

1. Put a hoist with wheel cover side up.

2. Unscrew three nuts [45] (with the spring washers [46]) fixing the wheel cover [44] and

remove the wheel cover from the side plate A [11].

3. Remove the hand chain [48] from the hand wheel [40].

4. Pull out the split pin [43] from the wheel stopper pin [42] and remove the wheel stopper

pin and the wheel stopper [41] from the pinion [17].

5. Remove the hand wheel [40] from the pinion [17] by turning the hand wheel

counterclockwise.

If the hand wheel is too tight to

turn by hand, put the hand chain on

the hand wheel back again and pull

it down hard. It will release the

brake.

WARNING