5

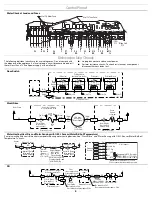

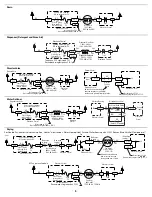

Drain

Dispenser (Detergent and Rinse Aid)

Diverter Valve

Water Softener

Drying

For Heated Dry, heater is also running. See “Heater” circuit under “Water Heating/Heat Dry and Water Sensing with O.W.I. Sensor (Water/Air/Soil/Temperature).”

L1

BK

P4-2

P6-3

P10-1

P6-1

P4-1

BR

BR

WH

N

Use top hole of jumper

W2 as test point for F9.

N.O.

K2

Pilot L1 Relay

(Also see Door

Switch Circuit)

Fuse

F9

Electronic Control

Electronic Control

No test pad on P6-3.

Recommend using test pad on P10-1.

Pin 1

Pin 3

Drain Motor

15

Ω

- 60

Ω

120V, 60 Hz, 60W

Triac

N

P4-1

Pin 1

Pin 3

N.O.

K2

P4-2

P9-3

P9-1

BK

L1

P10-1

Fuse

F9

Dispenser Wax Motor

1.4K

Ω

- 3.0K

Ω

120V, 60 Hz, 10W

Pin 1

Pin 5

Triac

Electronic Control

Use top hole of jumper

W2 as test point for F9.

Pilot L1 Relay

(also see Door

Switch Circuit)

Test pad on P9-3 might crowd P9-1

Recommend using test pad on P10-1.

Dispenser Solenoid

260

Ω

- 300

Ω

120V, 60Hz, 17W

Electronic Control

VI

VI

WH

Electronic Control

Sensor

Input

Switch closes momentarily

and then reopens as the diverter

reaches each potential diverter position.

Diverter

Position

Switch

Electronic Control

No test pad on P11-3.

Recommend using test pad on P11-2.

P11-4

P11-3

P11-2

5V

N.O.

Diverter Sensor

Diverter Motor

L1

BK

P4-2

P7-4

P10-1

P7-6

P4-1

N

WH

BU

BU

Pin 3

Pin 1

Use top hole of jumper

W2 as test point for F9.

N.O.

K2

Pilot L1 Relay

(Also see Door

Switch Circuit)

Fuse

F9

Electronic Control

No test pad on P7-4.

Recommend using test pad on P10-1.

Electronic

Control

Triac

Diverter Motor

1,100

Ω

- 1,400

Ω

120V, 60 Hz, 3W

L1

Regeneration Valve

BK

P4-2

P7-3

P10-1

P7-1

P4-1

N

WH

V

V

Use top hole of jumper

W2 as test point for F9.

K2

Pilot L1 Relay

(Also see Door

Switch Circuit)

Fuse

F9

Pin 1

Pin 3

N.O.

Electronic Control

Electronic

Control

Triac

No test pad on P7-3.

Recommend using test pad on P10-1.

Regeneration Valve

890

Ω

- 1,090

Ω

120V, 60 Hz, 6W

Electronic Control

P11-2

P11-1

RD

RD

(RD)

N.O.

N.O.

5V

(Optional Flowmeter)

Sensor

Input

(Closed when salt low)

Salt Level Reed Switch

39 K

Ω

Salt Level Sensing

Pin 1

Pin 1

Pin 4

Pin 2

Pin 3

Pin 3

Electronic

Control

(RD)

L1

BK

P4-2

P10-1

P10-3

P4-1

BR

BR

WH

N

Use top hole of jumper

W2 as test point for F9.

N.O.

K2

Pilot L1 Relay

(Also see Door

Switch Circuit)

Fuse

F9

Electronic Control

Electronic Control

(Red stripe

on plug)

(Red stripe

on plug)

Pin 5

Pin 1

Vent Wax Motor

600

Ω

- 1,800

Ω

120V, 60 Hz, 6W

Electronic Control

Electronic Control

(Red stripe

on plug)

(Red stripe

on plug)

P10-5

P10-4

P11-5

DC Ref

BR

BR

Pin 1

Pin 3

Fan Motor

31K

Ω

- 41K

Ω

5 VDC, 1W

Must measure resistance

with correct polarity and

disconnected from controls.

5V

_

+

Vent

Fan

No test pad on P10-4.

Recommend using test pad on P11-5.

L1

BK

P4-2

P7-3

P10-1

P7-1

P4-1

N

WH

BU

BU

K2

Fuse

F9

Pin 1

Pin 3

N.O.

Electronic Control

Electronic Control

Triac

No test pad on P7-3.

Recommend using test pad on P10-1.

AC Fan (not on all models)

Fan Motor

60

Ω

-

80

Ω

120 V, 60 Hz, 12 Watts

Pilot L1 Relay

(Also see Door

Switch Circuit)