Chapter 2 Basic Operation

2-10

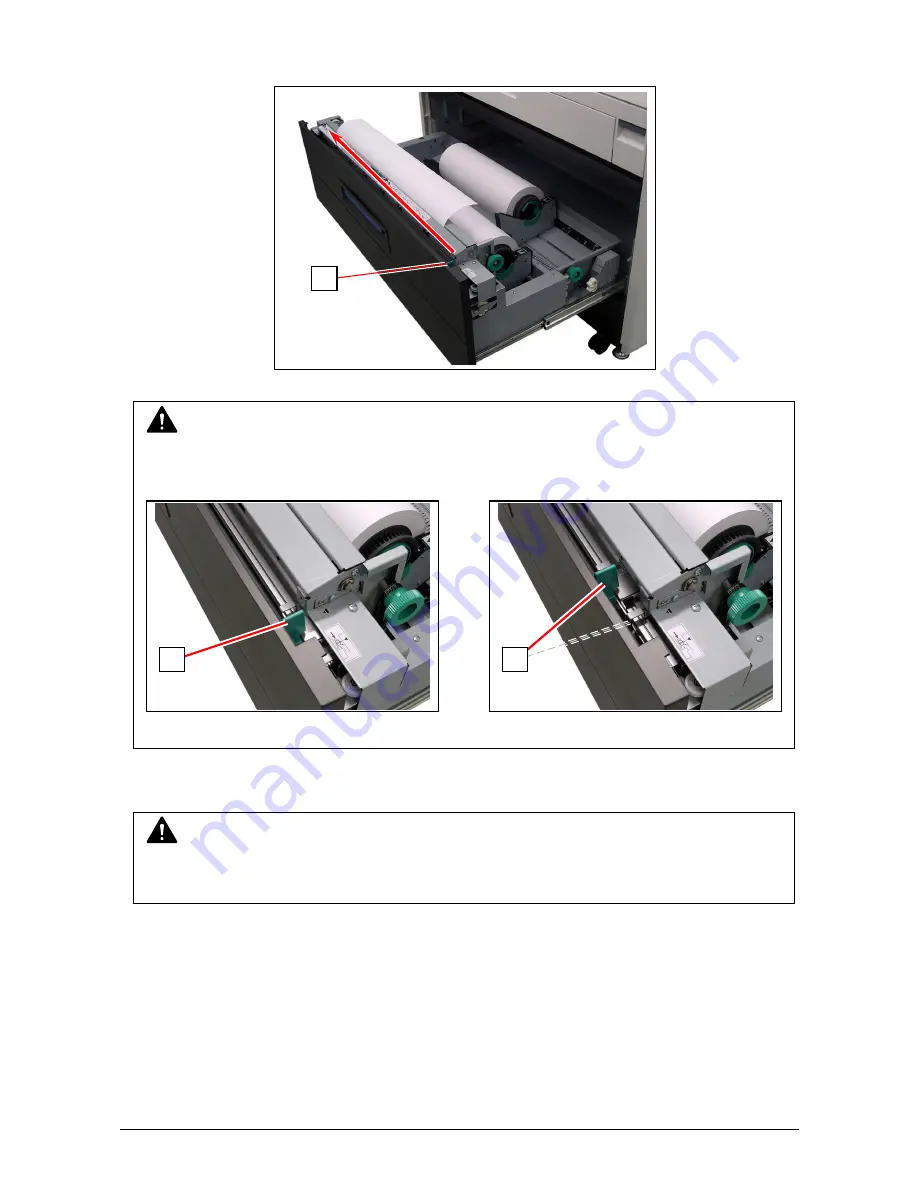

9. Slide the green Cutter Knob (12) fully from one side to the other to make a new straight edge.

Remove the cut portion.

10. Gently close Roll Deck.

NOTE

Completely slide Cutter Knob (12) until it stops at either end.

Not doing so may cause a paper jam.

Correct Wrong

NOTE

Be sure to close the Roll Deck fully until it locks at the correct position.

A paper jam may occur if it is not locked firmly.

12

12

12