IDV26

LOGF27

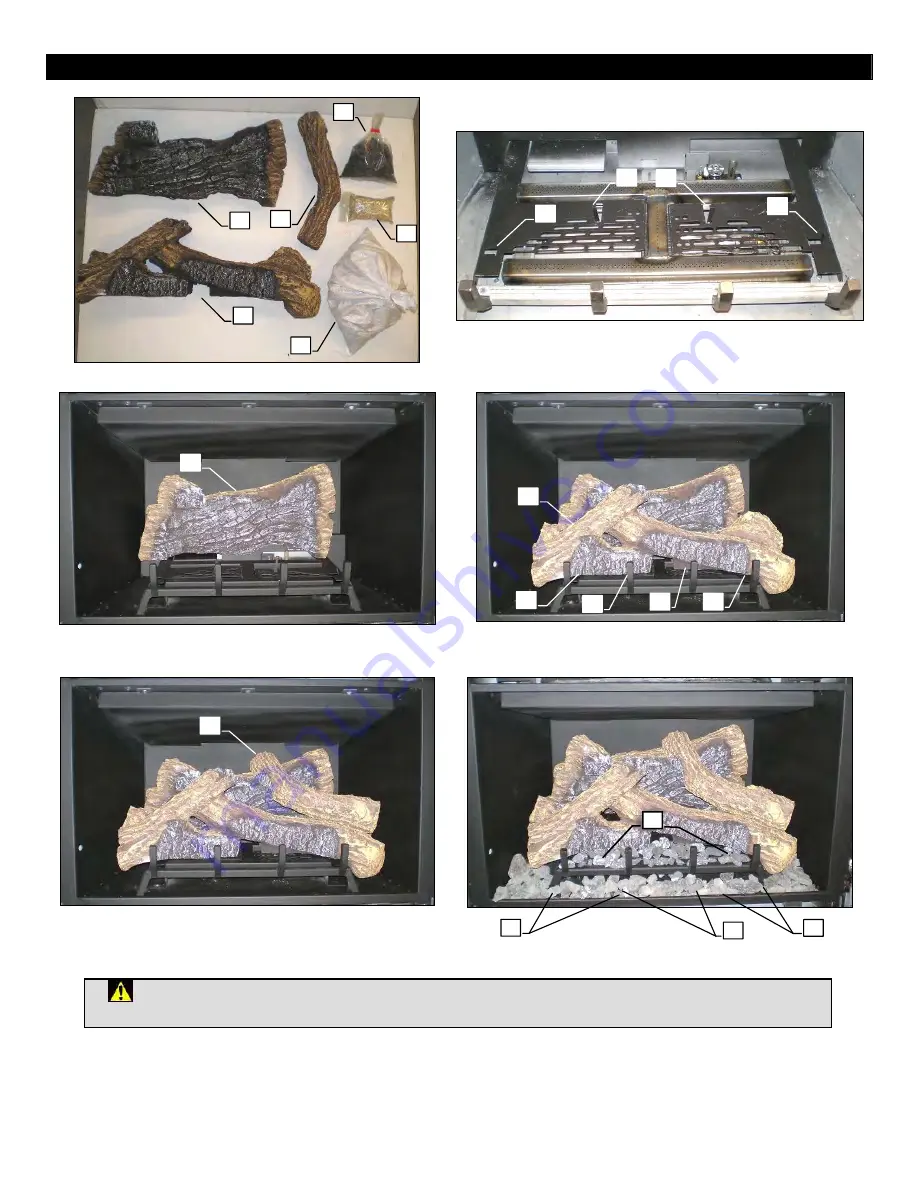

1

2

3

4

5

6

A

B

C

D

1

2

3

4

5

6

4

A

B

C

D

WARNING:

Failure to position the parts in accordance with these diagrams or failure to use only parts

specifically approved with this appliance may result in property damage or personal injury.

55