15

7.Risk factors

7.1Mecnanical dangers

The special two –hands control mechanisms minimizes risks and dangers related to moving

parts on the machine

An additional safety provided on the machine in order to prevent working with only one handle

while the other

one is being engaged (held down) by some mechanical tool or system .

DO NOTEVERATTEMPT to remove or by-pass the two-hands control Danger operating the

splitter without

the safety two-hands control will increase your risk of having your hands pinched during the

splitting cycle

Do not remove any other safety and protection device the machine.

WARNING splitting without due safety devices might result into serious injures to the operator or

the other person around the workplace .Keep hands and fingers clear at all time Many

log-splitting accidents happen on the

return portion of the stroke.

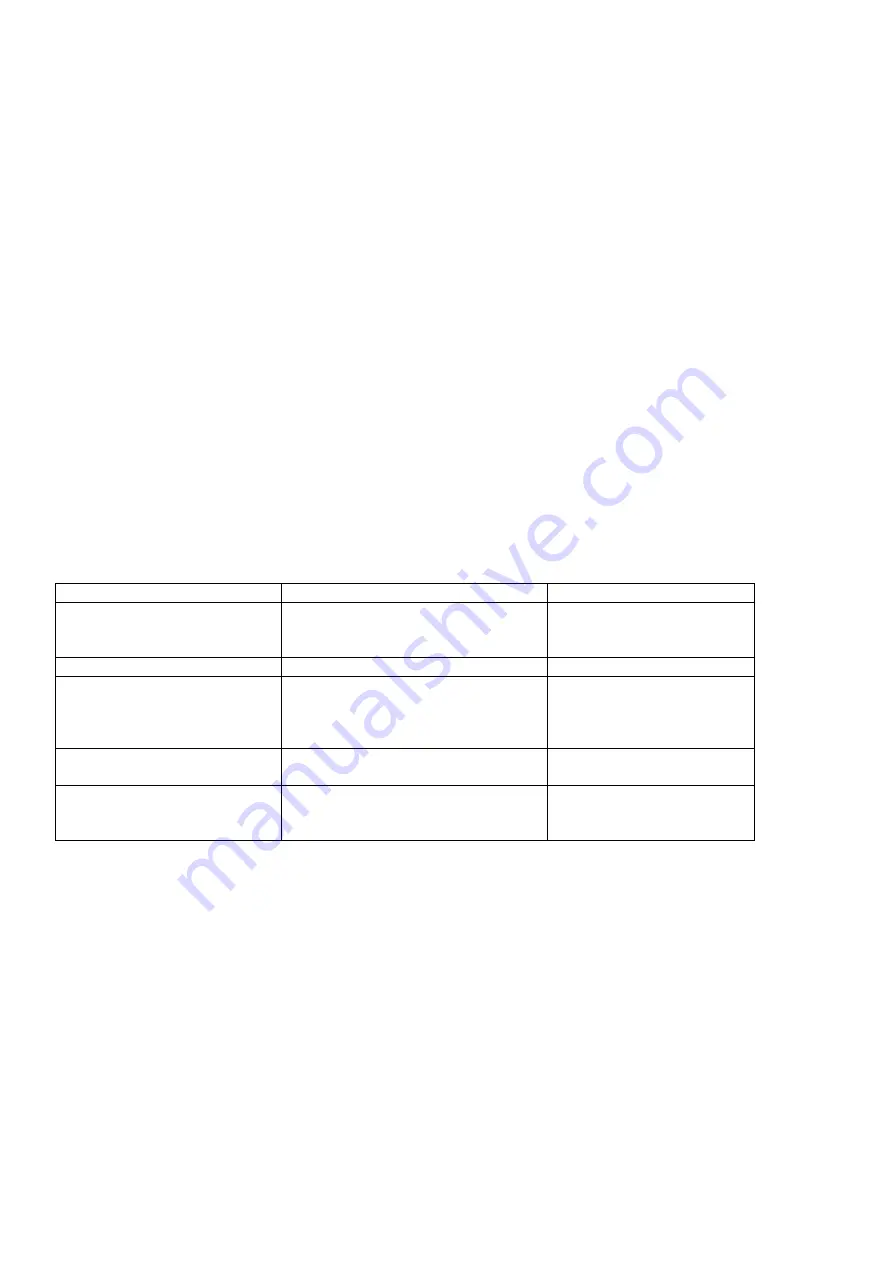

8.Trouble shooting chart

Type of malfunction

Possible origins of the problem

Solutions

When the control hands is

Pushed down. The wedge

Doesn’t tower

-Oil level is too

low

-Fill oil in

Ram won’t retract

See above

See above

Wedge moves slowly or

Will not extend completely

On normal log

-Oil level is too low

-Wrong valve détente

-Pump is broken

-Cylinder gaskets are damaged

-Fill oil in

-Adjust valve

-Replace pump

-Replace gaskets

Ram stops during

Splitting

-Log is too big, cragged or with

Lots of branches

-Turn/adjust log position

Hydraulic hoses

Heat-up excessively

-oil level too low

-Pump is damaged

-Wrong valve detente

-Fill oil in

-Replace pump

-Adjust valve

Summary of Contents for LS10TG

Page 3: ...3 4 5 6 7 8 9 ...

Page 14: ...14 Hydraulic Diagram ...

Page 16: ...16 ...

Page 17: ...17 ...