CHISEL & BIT

INSTALLATION/ADJUSTMENT

Chisel and Bit Installation

WARNING

: Make sure switch is in the

OFF

position and power cord is unplugged before

performing checks, adjustments, or setup procedures.

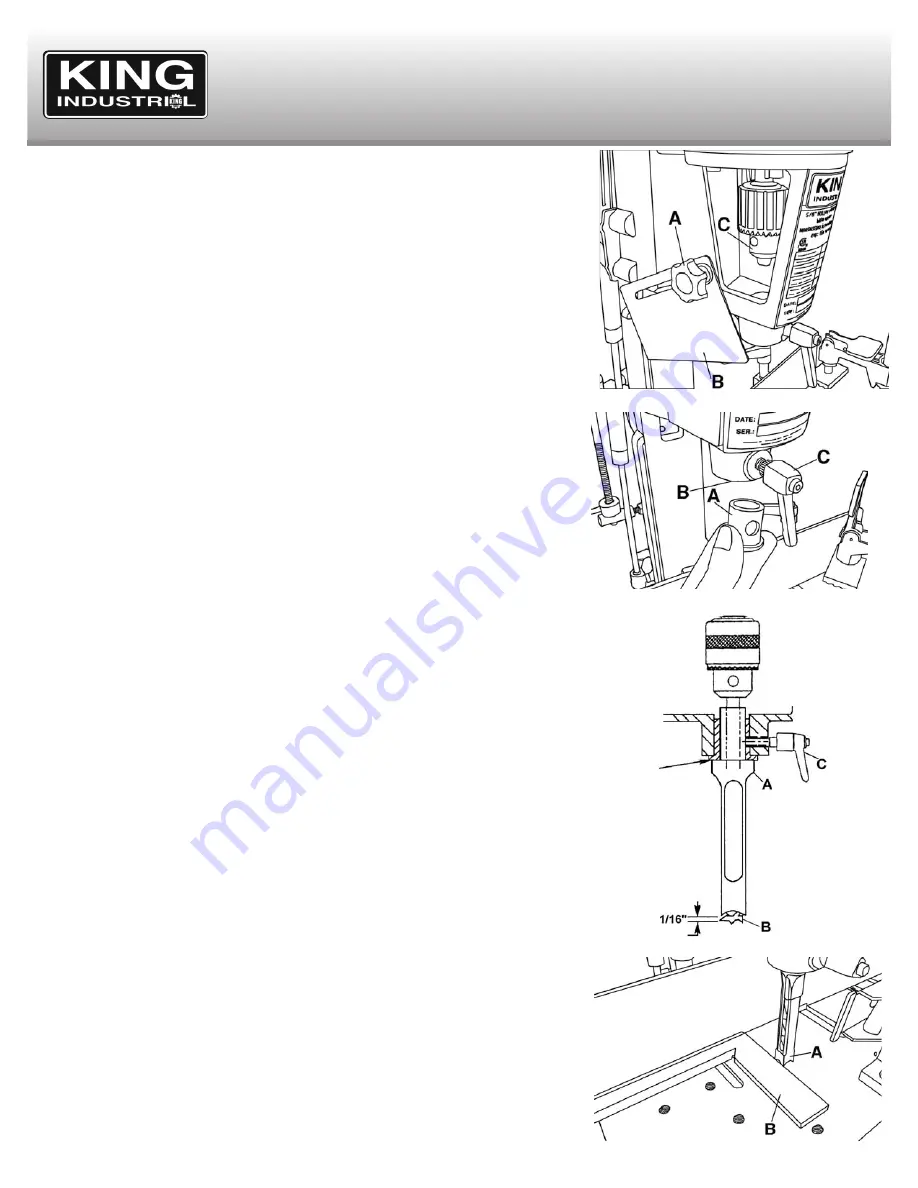

Loosen the two lock knobs (A) Fig.15 on both sides of the head and lower the covers (B)

to expose the chuck (C).

NOTE

: There are two different size chisel bushings provided. Determine which size fits the

chisel shank (5/8” or 3/4”) to be used and store the remaining one in a safe place for future

use.

Insert the appropriate chisel bushing (A) Fig.16 up through the hole in head (B), being sure

that round hole in the side of chisel bushing faces the front of machine. The lock knob (C)

must pass through this hole to secure chisel. Tighten the chisel bushing lock knob (C),

located on front of the head, until the chisel bushing is held up in place.

NOTE

: This lock knob should not become tight at this point. If it does, loosen it and retry,

making certain that the round hole in the side of the chisel bushing is lined up with the lock

knob.

Insert bit into chisel and insert chisel and bit up through hole in head assembly.

NOTE

: The opening in the side of the chisel should always be to the right or left, never to

the front or rear. The opening allows chips to escape during operation.

Push the chisel (A) Fig.17 up as far as possible into head, then lower chisel approximately

1/16". This setting is only temporary, the chisel will need to be repositioned against the

head once the bit is secure in place. Tighten lock knob (C) to hold chisel in position. Push

the drill bit (B) up through the chisel opening making sure that drill bit bottoms out in

chisel before bottoming out in chuck. Secure the bit in the chuck using the chuck key

supplied. Loosen lock knob (C) and push chisel up all the way into the head and retighten

lock knob. Refer to Fig.17.

NOTE

: Chisel was first lowered approximately 1/16" in the step above. The flat portion of

the bit should be adjusted to a minimum of 1/16" away from the bottom of the chisel. For

certain types of wood it may be necessary to increase this distance up to a maximun of

3/16" clearance. This assures having proper clearance between the cutting lips of the bit

and the points of the chisel.

Adjusting the Chisel Square with the Travel of the Table and the Fence

When the chisel is tightened in the machine, it must be square to the travel of the table and

the fence. First you must make sure the fence is set parallel to the travel of the table, the

easiest way to achieve this is to measure from the front edge of the table to both ends of

the fence.

Once you are certain the fence is parallel to the table, now you can proceed with setting

the chisel square with the fence. The easiest way to achieve this is to lower the head down

to bring the chisel (A) Fig.18 as close to the table as possible. Use the head height stop

bushing to hold it in this position. Place a square (B) against the fence and the side of the

chisel, loosen chisel lock knob, set the chisel square and and retighten lock knob.

Remember to have the chip ejection slot in the chisel to the side from which you will cut the

mortise.

Figure 16

Figure 17

Figure 15

Figure 18