EN

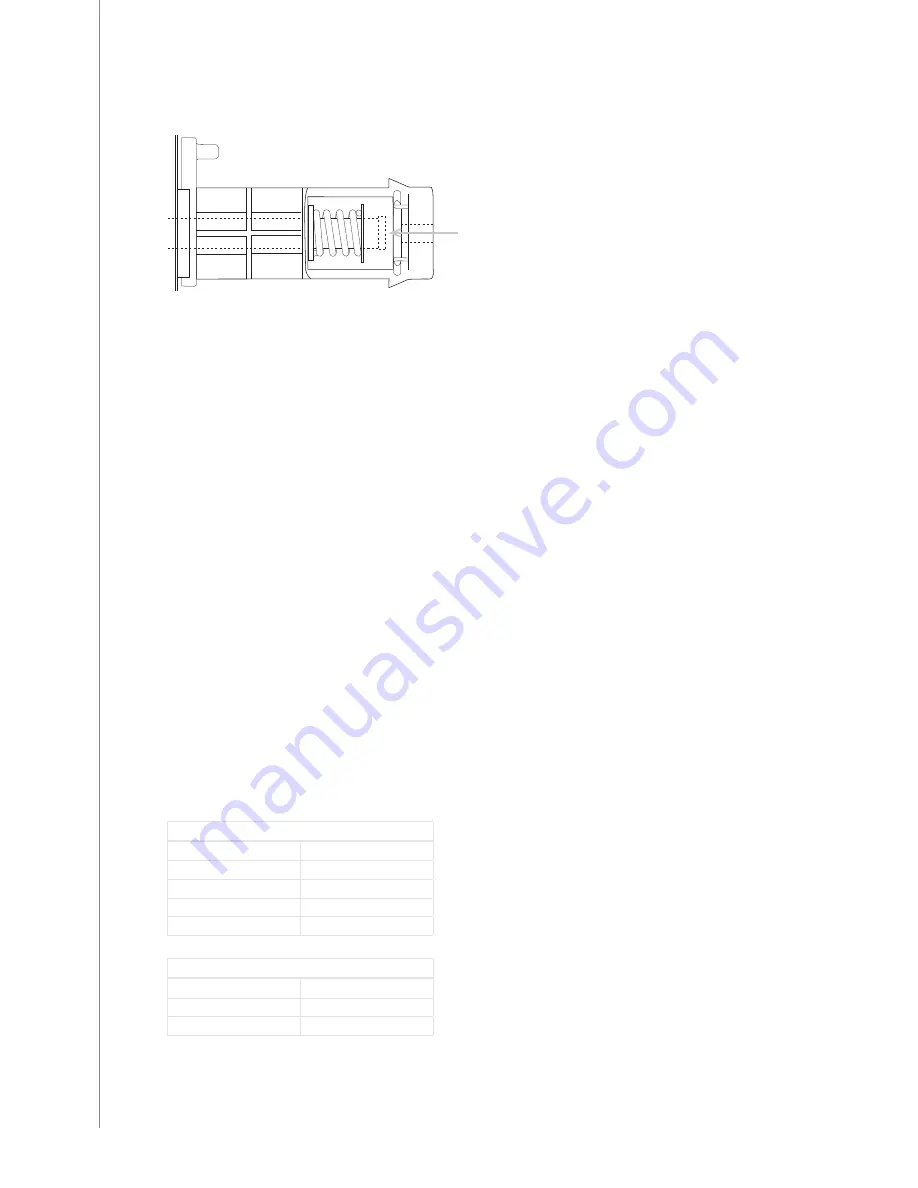

to adjust the spool brake in models 300, 300p and 300rC, do the following:

A

Adjust the spool brake force through the hole in the spool locking mechanism with a screw

driver. Increase by turning the screw clockwise and decrease by turning it anticlockwise.

3.4

reversing pOlArity

Polarity of the welding machine refers to the pole in which the welding cable is connected.

In MIG/MAG welding the gun is usually connected to the plus pole, i.e. you are using positive

polarity. However, some filler wires are recommended to be welded with the gun in negative

pole.

The Kemppi ArcFeed recognizes automatically the polarity you are using. This means that

it knows in which pole the welding cable is connected at the power source. The led on the

control panel indicates, whether you are using positive or negative polarity.

to reverse the polarity, do the following:

Switch the welding cable and earthing cable from one pole to the other at the power source.

After that, the wire feeder recognizes the new polarity, and indicates it with the control panel

led.

3.5

ChAnging the Feed rOlls

There are different feed rolls for different welding wires. Also, each feed roll has two grooves

for different wire sizes.

The Kemppi ArcFeed is equipped with standard feed rolls, which are equipped with plain

grooves. These feed rolls can be used in welding with all kinds of wires. There are, however,

following feed roll groove shapes available for special purposes:

•

Knurled groove is designed for cored wires and steel wires.

•

U groove is designed for aluminium wires.

•

Trapezoidal groove is designed for heavy welding applications.

The feed rolls and the wire liners have following colour codes in order to make identification

easier.

Feed rolls

colour of filler wire

ø mm

white

0.6 and 0.8

red

0.9, 1.0, 1.2

yellow

1.4, 1.6, 2.0

black

2.4

Wire guide tubes

colour of filler wire

ø mm

orange

0.6-1.6

blue

over 1.6

8

A

rcF

eed 200, 300, 300P

, 300R

C / © Kemppi O

y / 1117