3

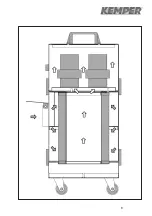

• The free air outlet at the blow out grating should not be constrained by any item.

• Don’t use the filter unit with closed suction opening or if the suction hoses are plugged.

• Never operate the machine without filter cartridges. Air contaminations lead to damages

to s.o.’s health or destruction of the turbine!

• Dispose the filter cartridges according to the legal regulations.

• Don’t use the unit to extract oil mist containing welding fumes, as well as during the WIG welding

procedure of stainless steel.

• Don’t use the unit for extracting easy flammable or explosive gases or dusts as e.g. aluminium

dust and wood dust.

• Don’t use the unit for the extraction of burning or glowing substances as e.g. cigarettes, matches,

metallic dusts or rather splinters, sheets of paper, cleaning tissues, etc.

• Don’t use the unit to extract sparks (e.g. of a grinding process).

• Don’t use the unit to extract aggressive substances.

• Don’t use the unit to extract any liquids.

• Don’t use the unit to extract organic substances

• For extraction of carcinogenic welding dusts (e.g. materials containing nickel or chromates)

you have to observe the regulations of TRGS 560 “Recirculation of air during working with

carcinogenic hazardous substances”.

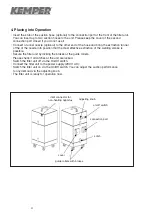

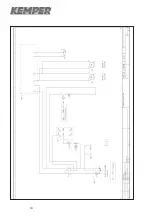

3. Operation Elements and Function

ON/OFF – switch

Monitor light for saturation of filter cartridges

The saturation of the filter cartridges will be checked continuously during the operation of

the unit. The cleaning of the filters is necessary as soon as the monitor light is activated.

(For cleaning see chapter 6, page 6 „Cleaning of filter cartridge“)

Adjusting knob for suction performance

The suction performance can be adjusted to the individual application by using

the adjusting knob.

= higher suction performance

= lower suction performance

2

3

O

I

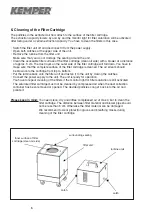

Filterüberwachung

Filter monitoring

Contrôle de

saturation des filtres

Absaugleistung

extraction capacity

Puissance d’aspiration

5

1

2

3

4

6

Von-Siemens-Str. 20 · D-48691 Vreden

Tel. +49 (0) 25 64 / 68 - 0 · Fax +49 (0) 25 64 / 68 - 120

[email protected] · www.kemper.de

welding, cutting and more...

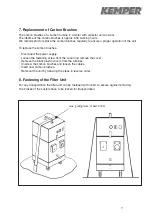

nächste Wartung

next maintenance

prochaine révision

Dusty

1

1

2

3