16

Commissioning Procedure

Installed correctly the burner should not emit any

fumes into the room. The following procedure should be

undertaken to test that the unit is operating correctly.

1

After unit has been operating for a short period a

smoke match, smoke tube, carbon dioxide analyser

or similar should be directed at the top opening of

the unit.

2 This procedure should be undertaken with the following

conditions in the room:

• Open or closed windows

• Operation of extraction/exhaust fans, range hoods

etc

• Operation of other gas appliances

• Operation of optional appliance fan at any speed.

3

Should any spillage be detected the cause must be

rectified before allowing commissioning of unit.

4. Please test appliance operation before leaving.

2

Initially the Kemlan coal fire may burn with a

slightly blue flame. After approximately 20

minutes the fire will settle down and burn with a

yellow flame.

3

As with all gas fires your gas coal/pebble or log

fire should be regularly serviced. We

recommend once each year. Service information

for an authorised person to follow has been set

out in attached leaflet.

4

PLEASE NOTE: Only logs provided by

Kemlan should be used with this appliance.

5

DO NOT place articles on or against this

appliance.

DO NOT use or store flammable materials

near this appliance.

DO NOT spray aerosols in the vicinity of this

appliance whilst it is in operation.

DO NOT modify this appliance. Primarily a

decorative appliance not certified as a space

heater.

6

The appliance is a live fuel effect product

designed to operate with luminous flames and

may exhibit slight carbon deposition.

7.

The guard is fitted to this appliance to reduce the

risk of fire or injury from burns and no part of it

should be permanently removed.

SERVICE - WARNING: ONLY TO BE SERVICED

BY AN AUTHORISED PERSON

Warranty

Provided the appliance has been correctly

installed according to instructions, Kemlan guarantee

the cost of replacing parts and the labour in

connection therewith for a period of 12 months from

the date of installation.

User Instructions

1. WARNING NOTE:

Properly installed and

operated this appliance will not leak gases.

Persistent fume emission must not be tolerated.

If fume emission does exist, then the following

immediate action should be taken.

A Open doors and windows to ventilate room.

B Turn the fire off.

C Check for flue blockage and clear if necessary.

D Do not attempt to relight the burner until the cause

of the emission has been identified and rectified.

Should assistance be required contact nearest

agent.

E The gas burner is designed to work in a Kemlan

Horizon electronic power flue ignition system.

Working correctly there will be no spillage. Unit

should cut out if not enough draw to ensure proper

functioning.

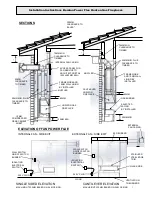

Installation Instructions Kemlan Power Flue Horizon Gas Fireplaces