10

Gas Installation

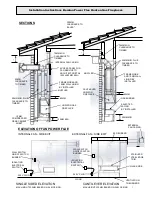

1 Check unit is suitable for intended gas supply.

2

Note position on gas appliance on drawing

specification on right hand side of appliance.

3

A gas cock has to be fitted prior to gas burner to allow

unit to be removed for servicing.

4

If material has been installed around firebox and

access panel below is not accessible the top plate

can be removed to gain access by removing four

screws and lifting out top plate.

5

Connection is half inch BSP fitting. Cut and deburr

both ends of pipe. Fit end to gas supply point and

turn on for approximately 5 seconds to clear dirt and

grit out of pipe. Connect into gas valve.

6

Turn on the gas and check all connections for leaks

using approved method for testing. Fix any leaks.

Adjusting Pressure, Pilot and

Low Fire

1

All settings are set to operate at nominal pressure

(see data plate). Test points to measure inlet

and outlet pressure are located on gas valve.

Unscrew brass screw on test point pressure

nipples and attach manometer and read pressures

with unit running. Adjust pressure to data plate

requirements.

2 Check low fire if adjusted correctly.

3

Note: Failure to set pressures correctly will void

warranty on the unit.

Lighting Instructions

Natural Draft Electronic Ignition Fireplaces are provided

with 240 volt electronic ignition systems.

An on/off wall switch is supplied and fitted with unit. The

fireplace is switched on from wall switch. Power is then

sent to valve to light pilot and main burner will then

ignite from pilot.

Burner is turned off by turning off wall switch. System

does not have a high low burner switch.

Laying the fire

–

Coal & Pebble

• Evenly spread a bag of Vermiculite into the burner

tray. Tray should be completely filled to the top with

Vermiculite to a depth of approximately 45mm.

• Unpack the coals/pebbles contained in a clear

plastic bag and lay a row of coals/pebbles on the

vermiculite along the back of the burner tray leaving

approximately 12-15mm between them.

• Leave spaces at the edges to allow free flow of gas.

• Place a further row of coals/pebbles directly in front

of the first row but staggered so that the second row of

coals are behind the gaps of the first row leaving

approximately 12-15mm between the rows of each

coal/pebble.

• Lay further rows of staggered coals/pebbles

depending on the size of the burner.

• Once the bottom layer is completed, build up 2-3

tiers of coals in a honeycomb pattern to form an

elongated pyramid.

• Lay the coals/pebbles so that some irregularity to the

pile through which the flames may lick, is created.

• Your aim is to build “windows” into the fire through

which the radiant effect may show but at the same

time, not leaving such large gaps between the coals/

pebbles that excessive air may enter and “damp down”

the red glow.

• After the fire has been alight for 15 minutes, you

may wish to add the odd coal/pebble or even relay the

fire completely. Allow to cool before touching the

coals/pebbles.

• Experience will enable you to obtain a pleasing

appearance with suitable heat output, but please bear in

mind that it is important to maintain the general

pattern described above and indicated in illustrations.

SEE NEXT PAGE FOR COAL & PEBBLE DIAGRAMS

Installation Instructions Kemlan Power Flue Horizon Gas Fireplaces