E r r - 1 4

DSP Read/Write

EEPROM failure

Turn off the system power, restart the system after 30 seconds, if it still does not

work, please replace the controller and inform the manufacturer.

E r r - 1 5

Motor over-speed

protection

E r r - 1 6

Motor reversion

E r r - 1 7

HMI Read/Write

EEPROM failure

E r r - 1 8

Motor overload

E r r - 1 9

Lack of oil alarm

Add oil to the needle rod, and set the P22 parameter at 4000, resume the

working time after the last oil adding; or you can press button P to close the

alarm and continue to use

4 Special function operating instructions

4.1 Upper stop position adjust

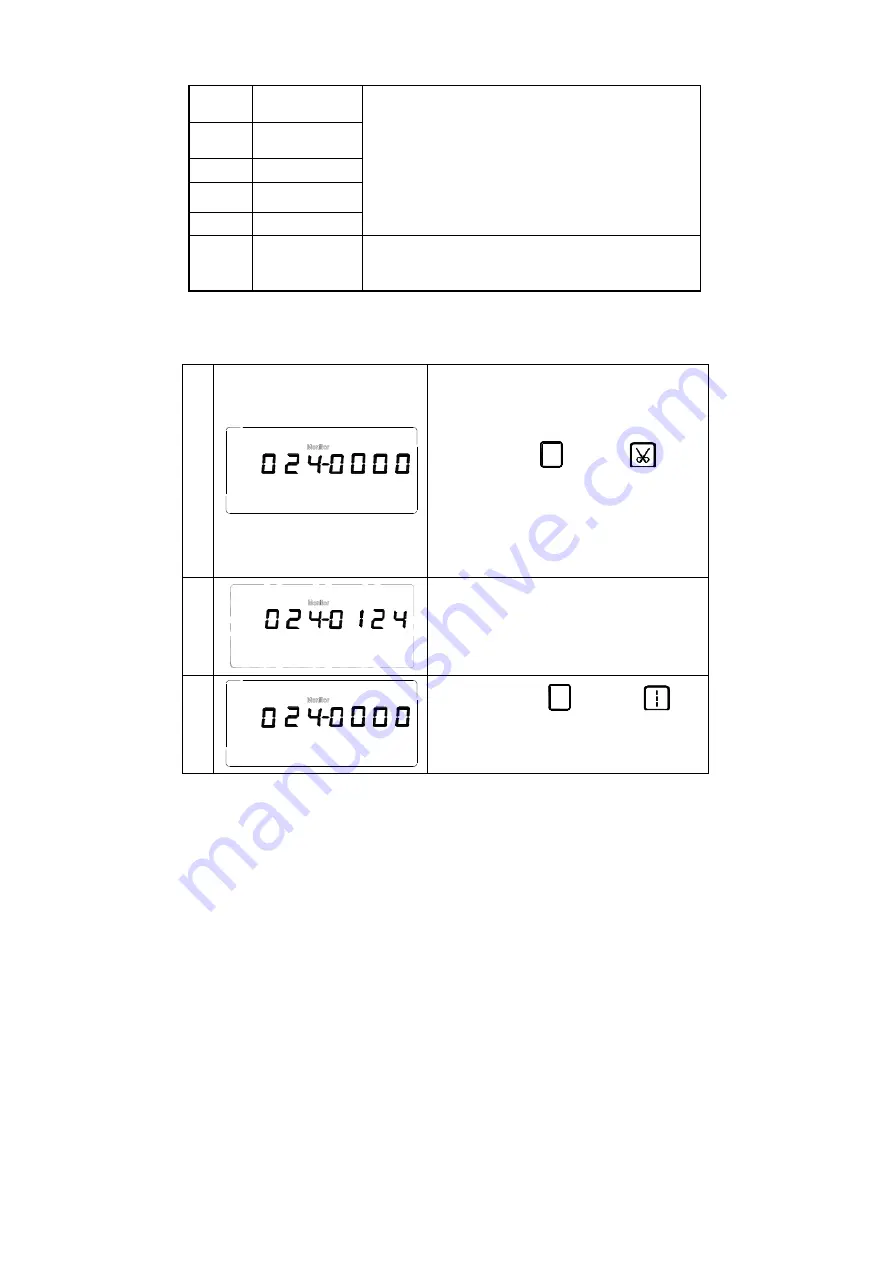

1

The control system in the recovery after the factory, according to

the need to re set the needle position!

P

The first step: first press

key, then press

key,

enter into monitor mode. The default is 024, monitoring

parameters, LCD screen displays the current point of view, such

as 0 ° shows that this position is the system default on

the needle stop position

2

The second step: turn the hand wheel, let the thread take-up lever

to the needle stop position or hope appropriate position adjusting

to, the liquid crystal display screen adjustment of

needle position, such as 124 °

3

P

The third step: first press

key, then press

key,

make the mechanical deflection angle is zero, on needle

position set. Finally, according to the key to exit.

31