Chapter 1 Before Use

1-5

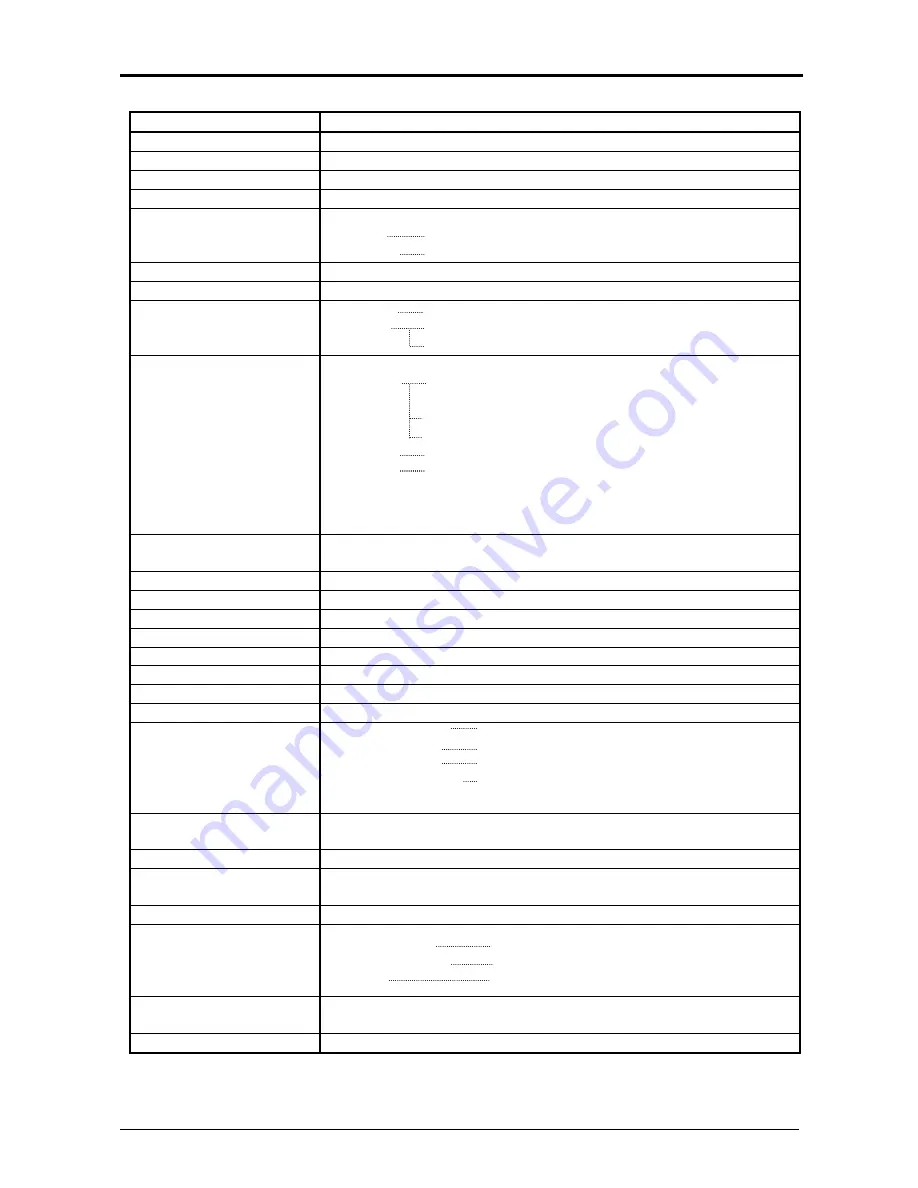

1. 4 Specifications

Subject Specification

Model KIP

7900

Configuration Console

Printing method

Electro photography

Photoconductor

Organic Photoconductive Drum

Print speed

160mm per second

(Inch)

E: 7 sheets/min

D Landscape: 12 sheets/min

(Metric)

A0: 7 sheets/min

A1 Landscape: 12 sheets/min

Print head

LED

Resolution 600dpi

Print width

Maximum

36” (914mm)

Minimum

Roll: 11” / 297mm

Cut sheet (Portrait): 8.5” / 210mm

Print length

Maximum

(Standard)

6,000mm (bond, 36” / A0 wide only)

or “5 x Standard length” (bond)

“2 x Standard length” (vellum)

“1 x Standard length” (film)

(Option) 24,000mm

/

Unlimited

Minimum 8.5”

(210mm)

NOTE:

If the print is longer than the maximum listed above, its

image quality or the reliability of paper feeding is not

guaranteed.

Warm up time

Less than 6 minutes

(23 degrees Centigrade, 60% RH and the rated voltage / Bond)

First print time

15.5 seconds (A0 from Roll 1)

Fusing method

Roll Fuser

Development method

Dry type with non-magnetic mono-component toner

Exposure method

LED

Charging method

Corona

Transfer method

Corona

Separation method

Corona

Input power

220V - 240V plus 6% or minus 10%, 50/60Hz, 15A

Power consumption

Maximum

3,600w

Stand by

1.3kwh (Average)

Printing 2.5kwh

(Average)

Cold sleep

14w or less

230V, 50/60Hz and Dehumidify Heater is ON

Acoustic noise

less than 67db (Printing)

less than 55db (Standby)

Ozone

less than 0.1ppm (Average)

Dimensions

1370mm (Width) x 700mm (Depth) x 965mm (Height) (w/o UI)

1385mm (Width) x 820mm (Depth) x 1590mm (Height, max) (w/ UI)

Weight

Approx. 386kg

Media (Recommended

Media)

Plain Paper US Bond (PB-20)

Tracing Paper US Vellum (XV-20)

Film 4MIL (PF-4DME)

Environmental condition

for usage

Temperature: 10 to 32 degrees Centigrade

Humidity: 15 to 85% RH

Interface

Ethernet (10 BASE-T, 100 BASE-TX, 1000 Base-T)

(continued on the next page)