3 – 3

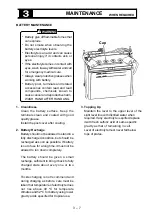

MAINTENANCE

3-2 RECOMMENDED LUBRICANT TABLE

REFILL

CHANGE LUBRICANT

LOCATIONS

CAPACITIES

INTERVALS

USE

VISCOSITIES

(APPROXIMATE)

Cold Regions

API, Class CD

SAE20

General

API, Class CD

SAE30

Tropical

API, Class CD

Regions

SAE40

Ambient

Wear Proof

Temperature

Hydraulic Fuluid

– 5 ºC

ISO – VG 46

Ambient

Wear Proof

Temperature

Hydraulic Fuluid

Below – 5 ºC

ISO – VG 32

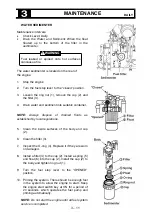

Track Rollers

0.025 liter

Upon

–

(Each)

occasion

Front Idlers

0.07 liter

Upon

–

(Each)

occasion

Travel Drives

0.33 liter

1000Hrs.

–

API, Class CD

(Each)

SAE30

Lubricate

Swing Bearing,

–

EP2 Lithium

the Fitting

Attachment pins, etc.

Grease

Note:

1. Oils in the hydraulic fluid columns marked with *should be use above 0 ºC.

2. If the oil becomes dirty or deterioration of the oil’s properties are excessive, replace more

frequently than described above.

3. Disassemble the track roller and upper roller when replacing the oil in them.

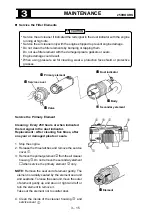

Max.

250 Hrs.

3.0 liter

Initial oil

Min.

change

2.0 liter

50 hours

Total

1000 Hrs.

Amount

Hydraulic

23 liter

(600 Hrs.

Oil

when

Tank Capacity

breaker

19 liter

used)

API, GL – 4 or GL – 5,

ISO – VG 320

(SAE 90)

Gear Oil

Diesel Engine

Summary of Contents for 17VXE

Page 2: ......

Page 62: ...2 1 8 ...

Page 110: ...5 1 HYDRAULIC SYSTEM DIAGRAM 5 1 HYDRAULIC SYSTEM DIAGRAM 2 9 30 ...

Page 118: ...MINI EXCAVATOR 17VXE PUBLISHED MARCH 2017 KATO IMER S p A ITALY ...

Page 119: ......

Page 120: ......