PowerKon QE

Assembly, installation and operating instructions

21

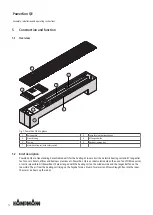

Terminal assignment X1

Terminal assignment X2

LED status messages

Terminal assignment X3

Dip switch

settings

Fig. 5: PowerKon QE circuit board

Terminal assignment

X1

mains

Mains connection (230 V/50 Hz)

X2

Fault

Potential-free fault alert output (max. load 60 V AC/DC 1 A)

Enable

DI1, potential-free enable contact

24 V

Voltage output 24 V DC ( max. 40 mA)

0 - 10 V

AI1, Control signal 0…10 V = Heat output 0…100% (Ri = 100 KΩ)

NTC 10K

AI2, temperature sensor

X3

Safety temper-

ature limiter

Safety temperature limiter

RPM

Input signal of the number of revolutions of the EC tangential fan

ERR

Input signal of the status of the EC tangential fan

24 V

Supply voltage (+) for the EC tangential fan

GND

Supply voltage (-) for the EC tangential fan

DIP switch settings

DIP

Factory setting

OFF

ON

DIP 1

OFF

Enable not required

Enable required

DIP 2

OFF

Speed increase Off

Speed increase On

DIP 3

OFF

Minimum heat output = 20%

Minimum heat output = 30%

DIP 4

OFF

Power reduction 100%

Power reduction 90%

Summary of Contents for PowerKon QE

Page 2: ......

Page 15: ...PowerKon QE Assembly installation and operating instructions 15...

Page 16: ...PowerKon QE Assembly installation and operating instructions 16...

Page 17: ...PowerKon QE Assembly installation and operating instructions 17...

Page 18: ...PowerKon QE Assembly installation and operating instructions 18...

Page 31: ...PowerKon QE Assembly installation and operating instructions 31...

Page 33: ......

Page 34: ......

Page 35: ......