- 14 -

- 7 -

KALVIS – 6MPP 2009.05.18

Boiler premises have to be well ventilated.

Recommenmded fuel humidity not greater than15-20 %.

Notice.

At the start of operation, until there is no soot layer on the

internal boiler surfaces, during combustion a water condensate may form,

giving the impression that boiler is not tight. Water vapour condensate will

disappear when water temperature in the boiler reaches 70-80°C. It is

recommended to keep water temperature in the boiler as high as possible.

When water temperature is below 55°C condensate will form intensely and

may cause acorrosion. In order to avoid low temperature corrosion, it is

recommneded to have an accumulation tank installed into a heating system,

in order to fire boiler at maximum output..

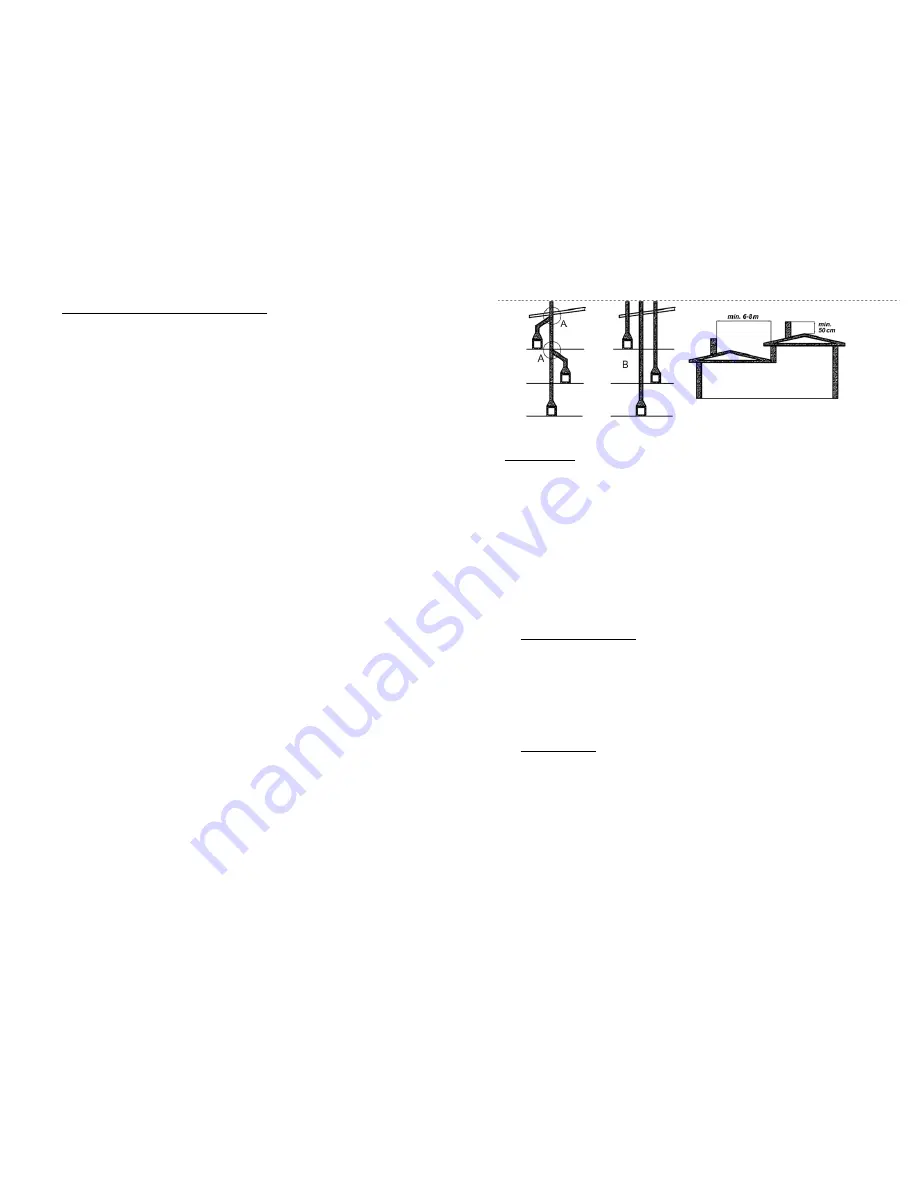

3c fig.

Requirements:

•

Chimney draught has to be no smaller than 22 Pa;

5.4.

Mounting and adjusting the draught adjuster

•

Chimney hole‘s cross section should be not less than 120 x 270 mm;

Draught adjusters manufactured by Swedish ESBE C20/25 with

protection from boiler overheating or without it are used. Adjuster is turned

into a socket, scotch tape is used for sealing, Attach chain to air supply

damper.

When boiler heats up to 70°C, adjust adjusters handle to position "4" and

shorten the chain so that, air supply damper is closed. Turning adjuster to

the correspondent position sets desired temperature. Position "6"

corresponds to 90°C. Temperature increment between positions is 10°C.

•

Boiler needs a separate hole for the chimney connection. No other

connections through that hole are allowed

•

If chimney is connected with additional elbow, it‘s cross section has to

be not less than that of the boiler smoke pipe, and bending radii not less

than 100mm;

•

Pipe from the smoke pipe to chimney has to be not longer than 1,5 m

and lean upwards toward chimney;

•

Joints have to be well sealed;

•

Chimney hole has to be well cleaned.

Necessary to know that:

5.5.

Boiler cleaning

(1 fig.)

To ensure optimum boiler performance slag has to be removed from the

burner and ash has to be cleaned from the internal boiler’s surfaces and ash

tray..

Intervals between boiler cleaning depend on fuel type and quality

(especially humidity), combustion intensity, chimney draught, etc. It is

recommneded to clean internal surfaces when soot layer on heat

exchangiong surfaces is no greater than 3mm. Remove service covers (p.4),

dampers (p.3; p.10) and carefully clean boiler surfaces.

Use special chemicals for hard residue cleaning.

Clean chimney at least once a year before heating season.

•

Smoke continues to cool in the chimney, vapor condenses on the

chimney walls, especially in the unheated loft and on the outside of the

building;

•

Condensate acids and erosion may destroy the chimney in few years;

•

Uncleaned soot in the chimney may self-combust and become the cause

of fire.

Recommended:

•

Mount an insert into the chimney. Well mounted insert protects chimney

from condensate influence;

5.6.

Troubleshooting

•

Insert should not significantly decrease the cross section of the chimney;

•

Insert parts should be well joined together (no soldering);

Boiler is protected against excessive pressure by protection valve and

expansion tank mounted in the system.

•

Condensate collector and drainage should be arranged in the bottom;

•

An incombustible material should insulate the cavity between the insert

and chimney. Top slit should be hermetically sealed;

•

In the unheated loft an incombustible material should insulate chimney.

Summary of Contents for 6 MPP

Page 9: ...12 9 KALVIS 6MPP 2009 05 18...

Page 10: ...10 11 KALVIS 6MPP 2009 05 18...