Maintenance and Troubleshooting

ProLine 2200 User’s Manual REV N

This information is subject to the controls of the Export Administration Regulations [EAR]. This information shall not be provided to

non-U.S. persons or transferred by any means to any location outside the United States contrary to the requirements of the EAR.

5-9

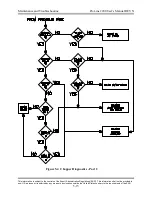

Troubleshooting Using the Microprocessor Error LED

If all of the status LED’s are illuminated but the ProLine system still has a

problem, remove the front panel of the power supply to gain access to the

microprocessor control board. The power supply microprocessor board displays

an error code by blinking LED22 on and off to indicate that an error has occurred.

The number of blinks can be counted to determine which error has occurred. The

following chart lists the errors and the corresponding number of blinks.

LED22 Number of Blinks

Error

1

No transferred arc (TAC) established

2

TAC lost before current slope up

3

TAC lost during current slope up

4

TAC lost while cutting

5

TAC lost during current slope down

6

Start signal applied prematurely or

while Gas Test/Run switch is in the

Run position

7

Start signal removed prematurely

8

Output voltage below 60V

9

Output voltage above 210V

10

Invalid current set point

11

Current feedback circuit open

12

TAC not established within 2 seconds

13

IHS or arc hold timed out

14

Pilot arc not established

15

Low current during cut

16

TAC sensed when start signal applied

17

Faulty AC phase

18

Low torch coolant flow

19

Gas console error

20

RHF door switch open

21

Low torch coolant level

22

High torch coolant temperature

23

Main contactor shorted

24

N/A

25

Defective Flow Switch