6

bow guard. Check that the saw blade is fitted with the correct direction of teeth. Make

sure that the saw blade type (dimensions 2450×27×0.9 mm) and its teeth pith are

suited to the material to be cut.

5.4 Electrical connection to the mains

Install a differential thermo magnetic switch with characteristics suited to the

mains.

Make sure that the power supply voltage corresponds to the voltage on the motor

plate. Connect the cable to the power supply line observing the color codes of the

individual wires, pay particular attention to the earth wire. Connect the machine, make

sure that the rotation of circular blade is in the direction shown by the arrow on the

guard.

5.5 Cutting coolant

For the cooling of the circular blade

,

fill the tank with emulsible oil obtained from a

mixture of water and AGIP ULEX 260 EP oil with a percentage of 5-7%

6. MACHINE START UP AND OPERATION

6.1 OPERATION

Checks to carry out before each cut

A Tension the saw blade by rotating #1 hand wheel to the end of stroke (mechanic

stop). Remember at the end of the operation to loosen the hand wheel to avoid the

slackening of the band.

B Check that the hand indicates the required cutting angle (vice scale).

C Make sure that the bow and the vice are locked by means of #136 lock handle

D With the motor off, lower the bow and check that at the end of stroke, the band

does not touch the counter-vice. If the band does touch, adjust #57.2 bolt located

on the bow.

E Make sure that the piece to be cut is properly secured in the vice.

F Make sure that the cooling liquid is circulating in the machine.

It is strictly forbidden to use the machine without cutting fluid

G When starting the motor, make sure that the band rotates in the direction of the

arrow

H

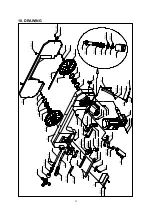

To obtain maximum cutting accuracy

,

the unit must be located the nearest

possible to the work piece. Clamp the work piece with the vice. Release #13 blade

guide arm with # 17 clamping lever and move it near the vice jaw so that it doesn’t

touch it during the cutting operation, then secure it again. When carrying out this

operation, make sure that the blade guide does not come out of the bow guard

leaving a part of the blade exposed.

6.2 CUTTING OPERATION

A. Before cutting, check that the inclination is the one required. In order to correct or

change the inclination, place #136 bench lever in position you expect and after