4

1.3 Emergencies according to European Standard “2006/42/EC”.

In the event of incorrect operation of danger conditions, the machine may be stopped

immediately by pressing the red emergency button.

The casual or voluntary removal of the blade cover of the flywheels causes the

stepping-in of a interlock switch that automatically stops all machine functions.

Note: resetting of machine operation after each emergency stop require specific

restart button.

2. DESCRIPTION OF MACHINE

2.1 Description of machine and its components

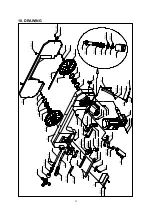

The band sawing machine produced by us has a sturdy frame made from welded and

painted sheet-steel. The upper surface is designed to allow the complete draining

away of the cutting fluid. The band holding bow is made of cast-iron and has generous

dimensions

,

providing the cutting unit with the necessary strength and precision. The

vice unit is made of cast-iron and clamps the material to be cut securely. The bar-stop

device allows the length required to be preset and a constant level of performance for

repeated cuts. The blade-holding bow is firmly attached to a reduction unit built onto

the motor and to the base by means of a joint which allows 60° rotation to the right.

This joint also allows the cutting movement to advance manually or by falling.

The coolant pump is fitted to the machine base. The main switch is located on the

front panel. The choice of one of the two motor rotation speeds and therefore cutting

speed is carried out by the main switch. The front panel is also fitted with an

emergency stop button and a START button. The control lever

,

fitted with an

ergonomic hand-grip and activation button with safety release action, reduces fatigue

during operation to a minimum. The blade is protected by a guard with interlock which

covers the upper area and the hand wheels and by two adjustable lower guards which

protect the operator from ejected shavings and coolant. The machine is supplied with

a set of service spanners.

2.2 Intended and unsuitable uses of machine

The band sawing machine has been designed and built to cut bars, structural steel

and ferrous metal pipes in accordance with the instructions contained in this manual.

Therefore, the cutting of other materials is not permitted: if the above

recommendations are not observed

,

the machine could be damaged and the health

and safety of the operator put at risk. Cutting is not permitted, if the bar has not been

first locked in the vice.

3. MAIN TECHNICAL DATA

Under no circumstances should the following data be altered, this is in order to protect

the correct functioning of the machine and to avoid creating safety risks for the

operator.